China Manufacturer for Toshiba IS450GS Used Injection Molding Machine for India Manufacturers

China Manufacturer for Toshiba IS450GS Used Injection Molding Machine for India Manufacturers Detail:

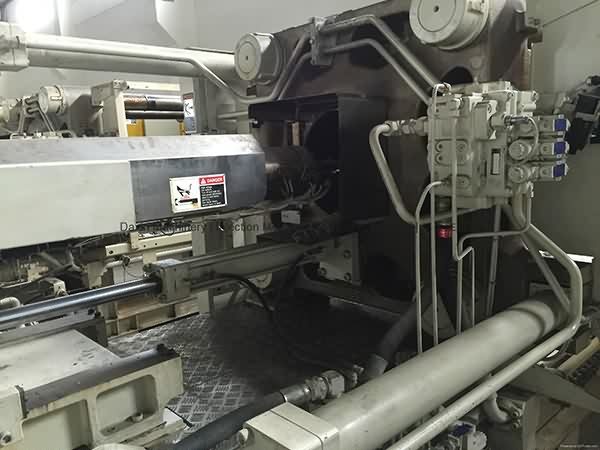

Toshiba 450t used plastic injection molding machine

Youtube: https://youtu.be/WJngGtO1BdI

Model: IS450GS.

Year: 2003.

Screw diameter: 70mm.

Injection weight: 1360g

Tie bar spacing: 810x810mm.

Controller: V10.

A few units for sale. Machines are in good working condition, kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us after Chinaplas to power on the machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

Plastic Injection Molding: Past, Present and Future

Always customer-oriented, and it's our ultimate goal to get not only by far the most reputable, trustable and honest supplier, but also the partner for our customers for China Manufacturer for Toshiba IS450GS Used Injection Molding Machine for India Manufacturers, The product will supply to all over the world, such as: Spain , Russia , Morocco , The company has perfect management system and after-sales service system. We devote ourselves to building a pioneer in the filter industry. Our factory is willing to cooperate with different customers domestic and overseas to gain better and better future.

Injection molding of a pen cap connector part from raw materials to finished pen cap part. This video features my new injection molding setup utilizing a 1 ton ...

https://www.AAdvantageLaundry.com.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!