China Manufacturer for Toshiba IS650GT Used Injection Molding Machine for Surabaya Factories

China Manufacturer for Toshiba IS650GT Used Injection Molding Machine for Surabaya Factories Detail:

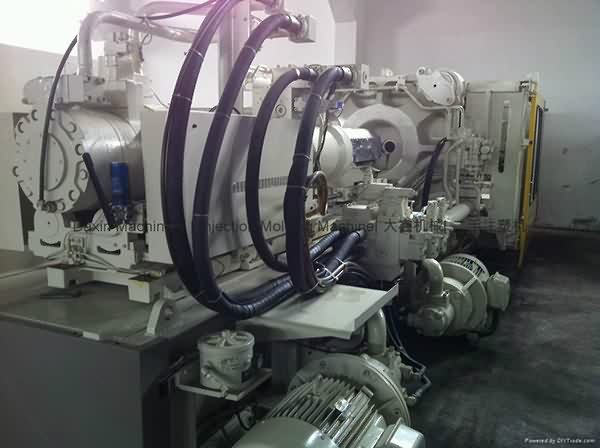

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT-59A.

Screw diameter: 90/95mm.

Tie bar spacing: 980x980mm.

Year: 2004/2006.

Controller type: V10.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Plastic Injection Molding: Past, Present and Future

Sticking to the principle of "Super High-quality, Satisfactory service" ,We are striving to generally be a very good business partner of you for China Manufacturer for Toshiba IS650GT Used Injection Molding Machine for Surabaya Factories, The product will supply to all over the world, such as: Albania , Saudi Arabia , New Zealand , Our products have mainly exported to south-east Asia Euro-America, and sales to all of our country. And depending on excellent quality, reasonable price, best service, we have got good feedback from customers overseas. You are welcomed to join us for more possibilities and benefits. We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

Plastic Granulator with Blower

This unit is a used plastic granulator with blower, powered by a 20-hp, 230/460 volt three-phase electric motor with controls. Throat opening is 18-1/2" x 14-1/2" with 3/4" screen. Feed hopper, stand and blower. Extra blades. Good condition. Excellent for plastics, HDPE, PET, PVC, light metals.

https://www.wwrequip.com/equipment/f290309.htm

www.sahilgraphics.com

www.sahilgraphics.tradeindia.com

We are old friends, the company's product quality has been always very good and this time the price is also very cheap.