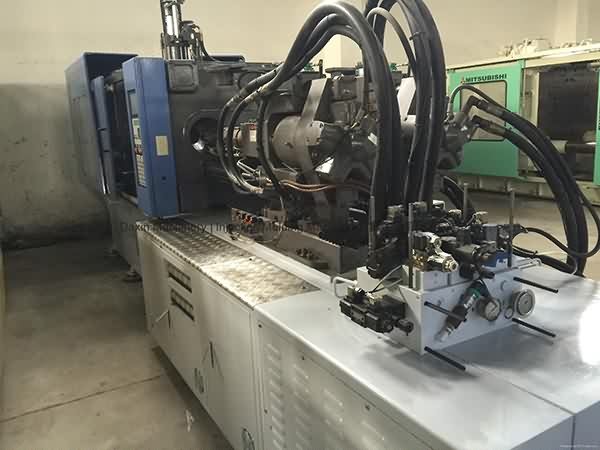

China New Product Hwa Chin 350t double-color used Injection Molding Machine Supply to Argentina

China New Product Hwa Chin 350t double-color used Injection Molding Machine Supply to Argentina Detail:

Taiwa Hwa Chin 350t Double Color used Injection Molding Machine.

Model: DC-350.

Year: 2010.

Screw diameters: 32/32mm.

Tie bar spacing: 650x650mm.

Diameter of rotary table: 950mm.

Very good running condition. Interested customer can visit our warehouse after Chinaplas to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

To consistently enhance the management method by virtue of the rule of "sincerely, fantastic religion and top quality are the base of business development", we extensively absorb the essence of associated goods internationally, and constantly acquire new merchandise to satisfy the needs of shoppers for China New Product Hwa Chin 350t double-color used Injection Molding Machine Supply to Argentina, The product will supply to all over the world, such as: Russia , Belarus , Durban , Please really feel free to send us your requirements and we'll respond to you asap. We have got a professional engineering group to serve for your just about every detailed needs. Cost-free samples could be sent for you personally to understand much more information. In an effort to meet your requires, please really feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd items. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is actually our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

ENGEL shows a fully automated production system of of PETRI plates. Mold has 4 cavities. Lids and bases are assembled and than packed in a plastic envelope.

Manual Plastic Embossing Machine Credit Card Embosser

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!