China OEM Toshiba 1300t (wide platen) used Injection Molding Machine to Mauritania Importers

China OEM Toshiba 1300t (wide platen) used Injection Molding Machine to Mauritania Importers Detail:

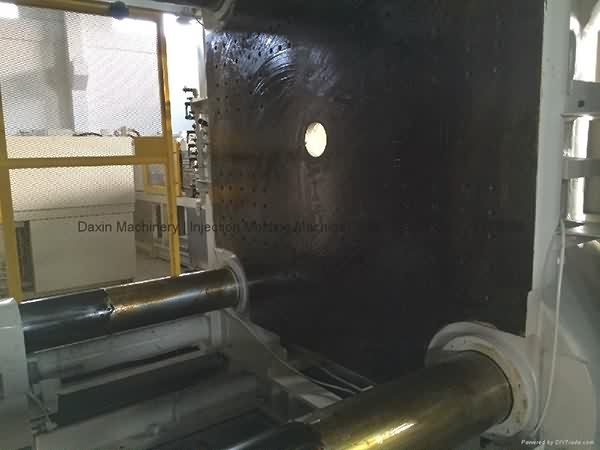

A Toshiba 1300t (wide platen) used injection molding machine for sale.

Model: IS1300DFW-200A.

Year of manufacture: 2004.

Screw diameter: 140mm.

Shot weight:9150g.

Tie bar spacing: 1430x1430mm.

Youtube video: https://youtu.be/hRc5cZvXlFs

Machine has wide platen, it is in good running condition. Interested customer is welcome to visit our warehouse to inspect and test run the machine.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

"Quality 1st, Honesty as base, Sincere company and mutual profit" is our idea, in an effort to create consistently and pursue the excellence for China OEM Toshiba 1300t (wide platen) used Injection Molding Machine to Mauritania Importers, The product will supply to all over the world, such as: Dubai , Los Angeles , Plymouth , Our stock have valued 8 million dollar , you can find the competitive parts within short delivery time. Our company is not only your partner in business, but also our company is your assistant in the coming corporation.

Interlocking Tiles Making Machines and interlocking Tiles Plastic Moulds manufactures in India.

contact us for Concrete Floor Tile mould, Concrete Floor Tile Rubber mould, Designer Floor Tile Plastic mould, Designer Floor Tile PVC mould, Designer Floor Tile Rubber mould, Floor Tile Plastic Mould.

www.srikrishnaplasto.com , info@srikrishnaplasto.com

Precast Concrete pavers making machines and Precast Concrete pavers making process for newly started business.

Plastic mould for interlocking tiles available in different shape and sizes . Interlocking Paver Moulds, Parking tiles moulds, plastic moulds for wet casting, Plastic Paver Moulds, precast paver mould, Rubber Moulds for wet casting, Rubber Paver Moulds.

The lipstick cases have been metallized.------------by

Jane Liu

Hongfeng Mechanical Equipment Manufactory

Website: www.hfvacuum.com

E-mail: info@hfvacuum.com

Address: No.6, Fulin East Road, Jiuhua Industrial Zone, Xiangtan, Hunan, China, 411100

MOBILE(Whatsapp): +86 13789 322 422 Skype: ljieerr

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!