China wholesale JSWJ450EIII used Injection Molding Machine for Amsterdam Importers

China wholesale JSWJ450EIII used Injection Molding Machine for Amsterdam Importers Detail:

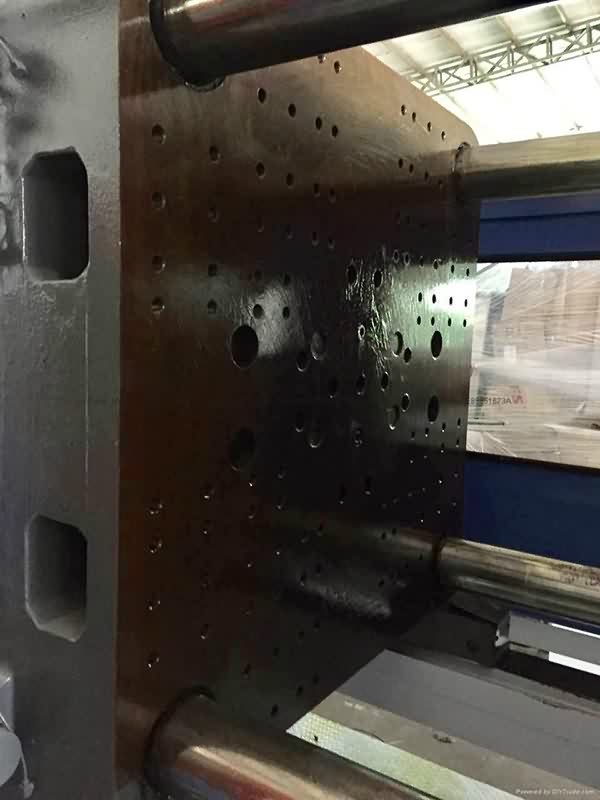

JSWJ450EIII used Injection Molding Machine.

Video:https://youtu.be/CXCqYjH1cto

Model: JSWJ450EIII.

Year: 2006.

Screw diameter: 84mm.

Tie bar spacing: 810x810mm.

Machine is in very good working condition. Interested customer is welcome to visit our warehouse to inspect the machine and test it running under power.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

The Precision of Plastic Machining

We know that we only thrive if we could guarantee our combined price tag competiveness and quality advantageous at the same time for China wholesale JSWJ450EIII used Injection Molding Machine for Amsterdam Importers, The product will supply to all over the world, such as: Moldova , Chile , Kenya , we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, we've gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

Milacron VL600-76, 600ton, 95 ounce, CAMAC VEL controls, new 1994. for sale by owner 586.228.2100.

TCM SHREDDER: https://www.tcmshredder.com/ a professional manufacturer, specialize in recycling shredder machine for more than 15years, Our produc ts are applicable for pet bottles, LDPE,HDPE, plastic lumps, ABS plastic, plastic films, mattress spring, etc. plays a big role in recycling industry, welcomed by domestic and national customers.

Main products:

1.singal shaft shredder

2.double shaft shredder

3.plastic crusher

4.plastic pipe shredder

5.four shaft shredder

6.plastic miller

7.plastic pulverzer

https://www.tcmshredder.com/

Tel: 0086 -21-61522014

Fax: 0086-21-61522018

Email: machineinchina@hotmail.com

Plastic Grinder Machine Plastic Recycling, Austria, hammer mill shredder for waste oil filters, JRS plastic grinder systems for plastic processing and recycling is a perfect machine to handle HDPE, LDPE, PVC, PET recycling, size reduction, and processing needs., indian hdpe pipe shredder, Plastic Grinding Machine, Plastic Grinding Bangladesh, ubc crusher machine, Plastic Grinding Machine, Wholesale Various High Quality Plastic Grinding Machine Products from Global Plastic Grinding Machine Suppliers and Plastic Grinding Machine, best grander for pp raffia beg crushing in india, China Plastic Grinding Machine, 2017 Plastic Grinding Dominica, shredder heavy duty abs plastic lump tow shaft, China Plastic Grinding Machine Select 2017 high quality Plastic Grinding Machine products varied in Processing Object, Abrasives and Controlling Mode from certified, textile shredder, plastic grinding machine, eBay Fiji, engine crusher, Find great deals on eBay for plastic grinding machine. Shop with confidence., plastic shredder big machine india with details, Plastic Grinding Machines Suppliers, Haiti, shredding soda machine, Find here details of companies selling Plastic Grinding Machines, for your purchase requirements. Get latest info on Plastic Grinding Machines, suppliers, shredding thin plastic, Plastic grinding miller machine Friend Machine Ireland, drum mold machine processing shredder, Plastic grinding miller machine, US $ 3, 500 11, 000 Set, New, Grinder, Jiangsu, China Mainland .Source from Zhangjiagang Friend Machinery Co., Ltd. on shredder, China Plastic Grinding and Washing Machine FW Series Jordan, hdpe scrap shredder, USAGE Plastic Grinding and Washing Machine is suitable to crush every kinds of hollow thin walled bottlescomma, car bumpers steel pipe materialscomma, big plastic, plastic shredder into small size, Used Plastic Grinding Machines, Used Plastic Liechtenstein, scrap engines shredder machine, Used Plastic Grinding Machines, Wholesale Various High Quality Used Plastic Grinding Machines Products from Global Used Plastic Grinding Machines Suppliers and Used, mini hdpe shredder, Plastic Grinding Machine Alibaba Mexico, plastic lumps shredder for big lumps, Plastic Grinding Machine, Zhejiang, China Mainland, sanbi, F 1 F 3 F 5 from Zhejiang Bangtai Machine Co., Ltd. on plastic hollow blocks, China Plastic Grinding Machine SWP150 SWP630 Niger, plastic bottle shredder untha, Zhangjiagang Fengcheng Machinery Manufacturing Co., Ltd. Plastic Grinding Machine, Plastic Grinding Machinery, Grinding Machine manufacturer supplier in China, , nylon bags shredder, Product Grinder Plastic Recycling, Grinding Nicaragua Commercial grinder manufacturer, Jordan Reduction Solutions offers grinding machine to grind plastic, wood, carpet, textiles, and other scrap for recycling, disposal China Plastic Grinding Machine for Recyling China Plastic New Zealand China Plastic Grinding Machine for Recyling, Find details about China Plastic Crusher, Film Crusher from Plastic Grinding Machine for Recyling Ruian Hengfeng Machinery Plastic Scrap Grinder Plastic Grinding Machine Pakistan Exporter of Plastic Scrap Grinder Plastic Grinding Machine, Plastic Scrap Grinders with Blower Attachment offered by Om Chamunda Enterprises, Mumbai, MaharashtraPlastic Grinding Machine, Crusher Mills, Cone Slovakia Inexpensive way to grind plastic bottles And the other is our Plastic Grinder web page which details all the specs about our plastic grinding F 4 Plastic Grinder Granulator Machine China Tanzania Ruian Mingde Machinery Co., Ltd. Plastic Crushing Machine, Plastic Grinding Machine, Plastic Recycled Machine manufacturer supplier in China, offering F 4 Plastic Grinder Crushing Machines Pharma Scrap Crusher UkraineExporter of Crushing Machines Pharma Scrap Crusher, Plastic Crushing Machine, Plastic Grinding Mills and Plastic Scrap Grinder Machine offered by Europack

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.