China wholesale Nanrong 250t used Injection Molding Machine for Sri Lanka Importers

China wholesale Nanrong 250t used Injection Molding Machine for Sri Lanka Importers Detail:

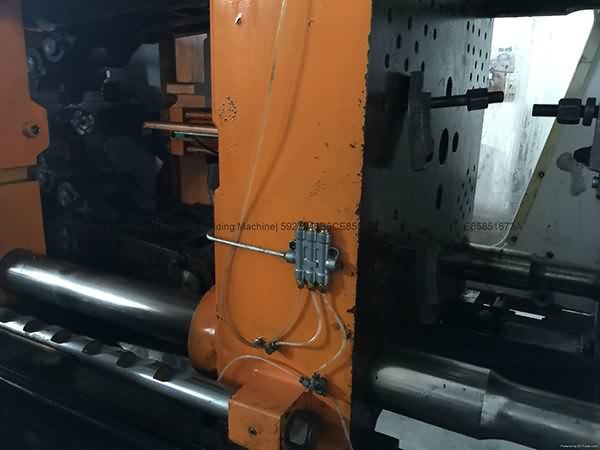

Taiwan Nanrong 250t used Injection Molding Machine.

Model: TNR250S.

Year: 2007 Dec.

Screw diameter: 48mm.

Tie bar spacing: 510x510mm.

Good running condition. Interested customer can visit our warehouse to inspect machine and power on for dry-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Making Plastic – Plastic Injection Moulding

We know that we only thrive if we can guarantee our combined price tag competiveness and top quality advantageous at the same time for China wholesale Nanrong 250t used Injection Molding Machine for Sri Lanka Importers, The product will supply to all over the world, such as: Philippines , Montreal , Riyadh , We have our own registered brand and our company is developing rapidly owing to high quality products, competitive price and excellent service. We sincerely hope to establish business relations with more friends from home and abroad in the near future. We look forward to your correspondence.

Amazing Milacron IMM Running with a High-Tech Stacking double cube mold technology "FANTÁSTICO" Injetora Milacron rodando com um Molde de alta ...

Plastic film crusher of MG PLAS can be used for kinds of waste plastic films such as HDPE films, LDPE/LLDPE films, PP films, PET films and PVC films, etc.

Supply ranges of Plastic film crushers in MG PLAS:

motor power:45kw/55kw/75kw/90kw

capacity range: 400kg/h to 1500kg/h for different models.

blades materials: SKD-II Korea or Japan.

main bearings position: external.

shaft: by dynamic balance testing.

machine weight range: 3000kg to 6500kg.

Configuration:

belt conveyor+ heavy wet plastic film crusher+ screw feeder.

independent control cabinet.

For more details of plastic film crusher in MG PLAS, please contact:

Mr.Gram Gao

Email: gram@vip.163.com,

Mobile&whatsapp:+86 13776255760

Skype: gramlg.

Please subscribe our YouTube channel for more updated videos.

Thank you very much.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!