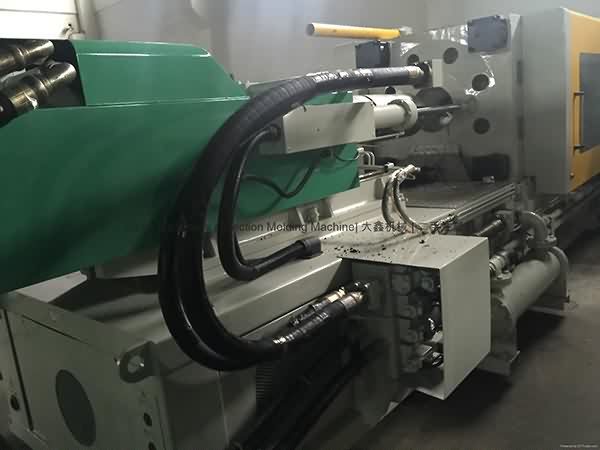

Chinese wholesale Chen Hsong Super Master SM450TS used Injection Molding Machine to Albania Manufacturer

Chinese wholesale Chen Hsong Super Master SM450TS used Injection Molding Machine to Albania Manufacturer Detail:

Taiwan Chen Hsong Super Master 450t used Injection Molding Machine

Video: https://youtu.be/lo5SPPvPMCo

Model: SM450TS.

Year 2009.

Screw diameter: 60mm.

Tie bar spacing: 820x820mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Plastic Injection Molding: Past, Present and Future

Adhering for the theory of "quality, services, performance and growth", we have received trusts and praises from domestic and worldwide shopper for Chinese wholesale Chen Hsong Super Master SM450TS used Injection Molding Machine to Albania Manufacturer, The product will supply to all over the world, such as: Ghana , Oman , Surabaya , Based on our automatic production line, steady material purchase channel and quick subcontract systems have been built in mainland China to meet customer's wider and higher requirement in recent years. We are looking forward to cooperating with more clients worldwide for common development and mutual benefit!Your trust and approval are the best reward for our efforts. Keeping honest, innovative and efficient, we sincerely expect that we can be business partners to create our brilliant future!

・ 月曜定例会・昼の部 - 日本製鋼所への抗議 - [ 2013.06.24 ]

【 お知らせ 】 Channel ☆ K [ https://www.youtube.com/ChannelK2013 ] にチャンネルを移転中です。しばらくは両方のチャンネルから動画をアップしますので、両方ともチャンネル登録を、よろしくお願いします。これからも武田さんのブログ音声、そして現場の映像撮影に努めます。 [ 2013年06月11日 / 清瀬 航輝 ]

場所 : 東京・大崎(昼の部)

日時 : 2013年06月24日(月) 正午過ぎ ~ 午後1時

説明 : 今回は月曜定例会の「昼の部」を撮影しました。なお「夜の部」も撮影していますので、ともにぜひご覧下さい。

・ 月曜定例会・夜の部 - 関西電力、中部電力、両東京支社への抗議 - [ 2013.06.24 ]

→ [ https://youtu.be/BFkkc3IP3cY ]

(以下転載)

脱原発は月曜定例会から、という事で定例の抗議です。

抗議は昼(大崎)と夜(関西電力東京支社&中部電力東京支社)の二部制となりました。

【 昼の部 】

日本製鋼所抗議

ゲートシティ大崎ウエスト(23Fが日本製鋼所本社) 12時 ~ 13時

JR大崎駅前 [ https://p.tl/jfA6 ]

【 夜の部 】

関西電力東京支社への抗議 19時半 ~ 20時半

中部電力東京支社への抗議 20時半 ~ 21時

(ともに地下鉄「内幸町」A7出口を出たところ)

となります。多くの皆様方のご参加を !

月曜定例会(非公式ブログ) [ https://okichi12.jugem.jp ]

撮影 : 清瀬 航輝 - Kiyose Kouki - [ https://kiyose-kouki.jimdo.com ]

(C) STARS LIFE 2013 All Rights Reserved.

[ 福島原発事故 , 福島第一原子力発電所事故 , 福島 , 福島県 , 原発事故 , 東日本大震災 , 東北大震災 , 震災 , 福島事故 , 原子力 , 脱原子力 , 反原子力 , 脱原発 , 反原発 , 原発反対 , 再稼働反対 , 原発再稼働反対 , 大飯再稼働反対 , 大飯原発再稼働反対 , 反原発デモ , 脱原発デモ , 反原発抗議活動 , 脱原発抗議活動 , 首相官邸前 , 官邸前デモ , 官邸前抗議活動 , 経産省前テントひろば , 反原連 , 月曜定例会 , 反被曝 , 脱被曝 , 安倍 晋三 , 安倍首相 , 安倍総理 , 核武装 , 自民党 , 自由民主党 , 日本製鋼所 , ゲートシティ大崎 , ゲートシティ大崎ウエスト , 原子炉メーカー , 軍需産業 , 軍需企業 ]

Automatic Stretch blow molding machines, pet blowing machines for wide mouth plastic jars

Features:

The Precision design of the elbow-type hydraulic clamping mechanism to ensure that the clamping force of the foot, the action is not smooth expansion.

The Slide drive to ensure smooth running, fast and accurate.

The Self-locking high-pressure sealing, sealing reliable, no impact, no wear; independent control of the drawing rod, stretching process control accuracy.

The With automatic bottle machine, optional automatic loading blank device, to achieve the production process fully automatic.

The A new generation of industrial-grade high-speed PLC control computer and Chinese and English touch screen operation interface, process time parameters set to accurate to 0.01 seconds, making the operation more intuitive, more accurate process settings.

The Part of the action part of the pneumatic components used in Europe or Japan high-quality components. High pressure blowing Germany quick response solenoid valve, so that the timing of the second blowing accurate control.

The Concentrated parallel heating to ensure uniform heating, stability, and minimize energy consumption.

The Closed-loop feedback precision instrumentation heating control, import high-power power module output to ensure stable heating and energy saving, not affected by voltage fluctuations. To the most effective infrared heating PET heating wavelength, in particular, customized heating lamp, to achieve the highest energy efficiency, fully consider reducing energy consumption and improve production efficiency.

Our Factory since 1992 has been manufacturing the cosmetic&food making and packaging machinery.In these field we have the experience rich enough to solve the questions encountered by our customers from both home and abroad.

For more information about penglai packaging, please visit our website at https://penglaipacking.com

SHENZHEN PENGLAI INDUSTRIAL CORPORATION LIMITED

Contact:Michael Peng Skype: penglaichina Email: penglaipacking@gmail.com whatsapp:+86-15012795261

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.