Competitive Price for Mitsubishi 160t used Injection Molding Machine for Azerbaijan Manufacturer

Competitive Price for Mitsubishi 160t used Injection Molding Machine for Azerbaijan Manufacturer Detail:

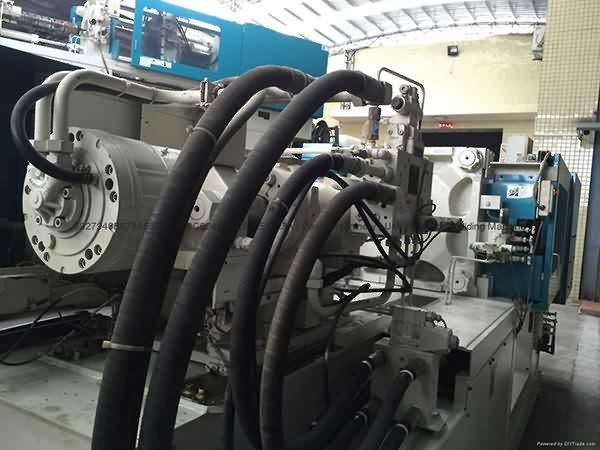

Mitsubishi 160t used Injection Molding Machines for sale.

Model: 160MSV.

Year: 2005.

Screw diameter: 45mm.

Tie bar spacing: 560m.

Very good running condition.

Interested customers can visit our warehouse to inspect the machine.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

That has a sound business enterprise credit rating, exceptional after-sales provider and modern producing facilities, we now have earned an superb standing amongst our buyers across the world for Competitive Price for Mitsubishi 160t used Injection Molding Machine for Azerbaijan Manufacturer, The product will supply to all over the world, such as: Bangladesh , Denmark , Slovak Republic , We have developed large markets in many countries, such as Europe and the United States, Eastern Europe and Eastern Asia. Meanwhile with the powerful predominance in persons with ability, strict production management and business concept.we constantly carry on self-innovation, technological innovation, managing innovation and business concept innovation. To follow the world markets fashion, new products are kept on researching and providing to guarantee our competitive advantage in styles, quality, price and service.

Jet Engine Automation Co., Ltd. www.jetrobot.com.tw.

new 2012 rubber boots a brand new vintage 80s rubber boots,

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.