Discount Price Haitian 1300t (servo) used Injection Molding Machine for Russia Importers

Discount Price Haitian 1300t (servo) used Injection Molding Machine for Russia Importers Detail:

Haitian 1300t (servo) used Injection Molding Machine for sale.

Model: MA13000/10500

Year: 2012.

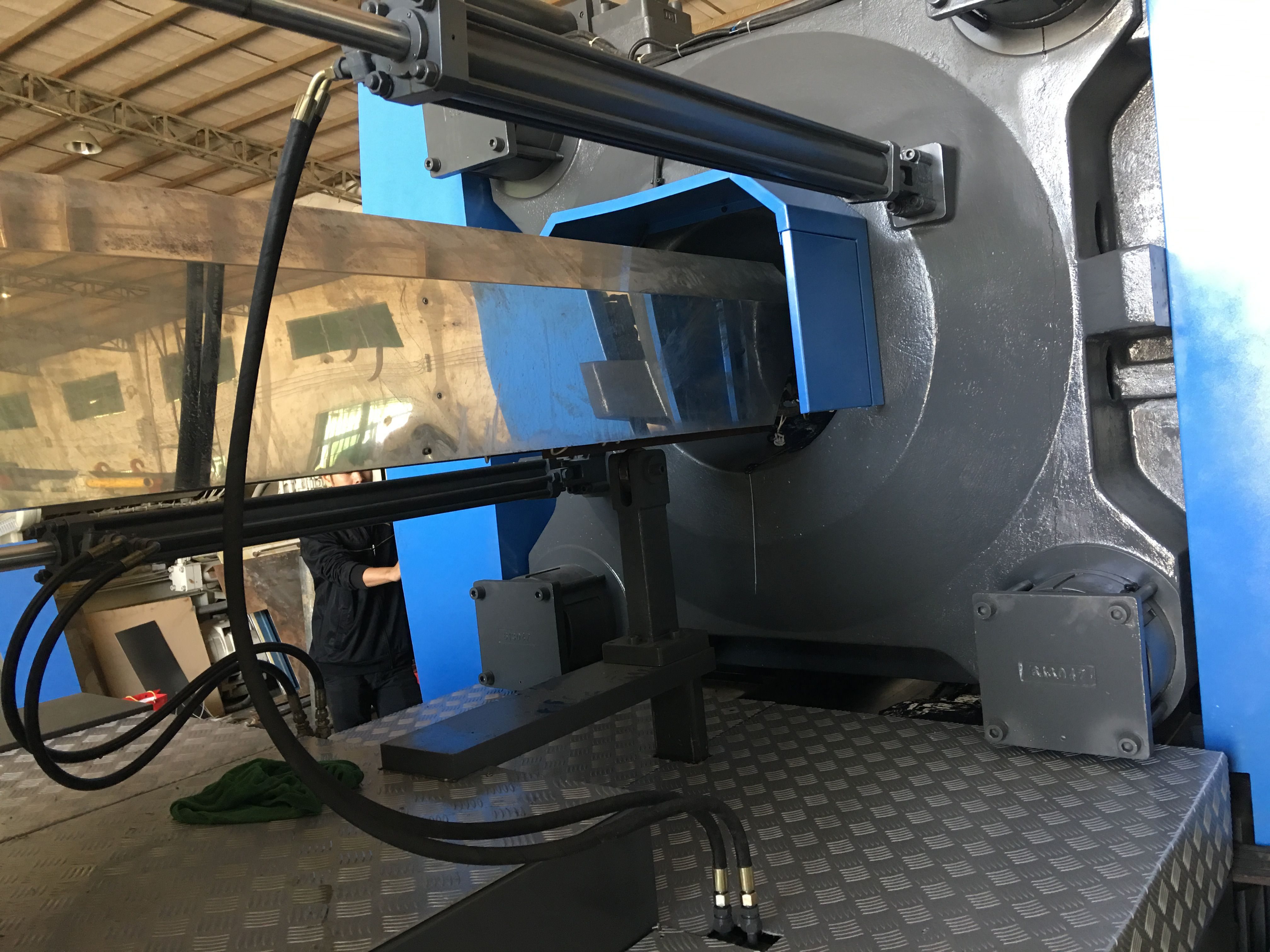

Tie bar spacing: 1250mm.

Still running production in factory. Good working condition.

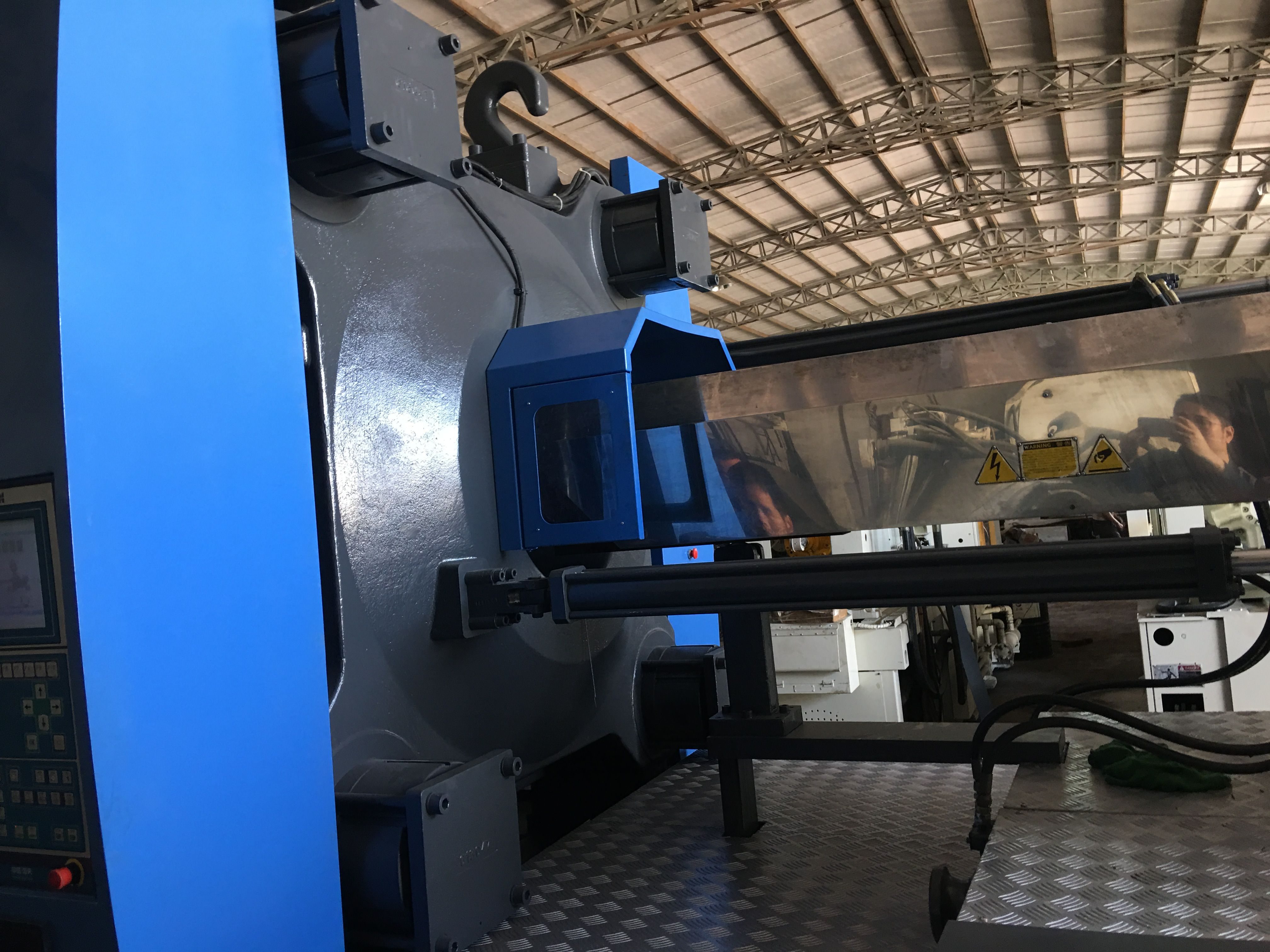

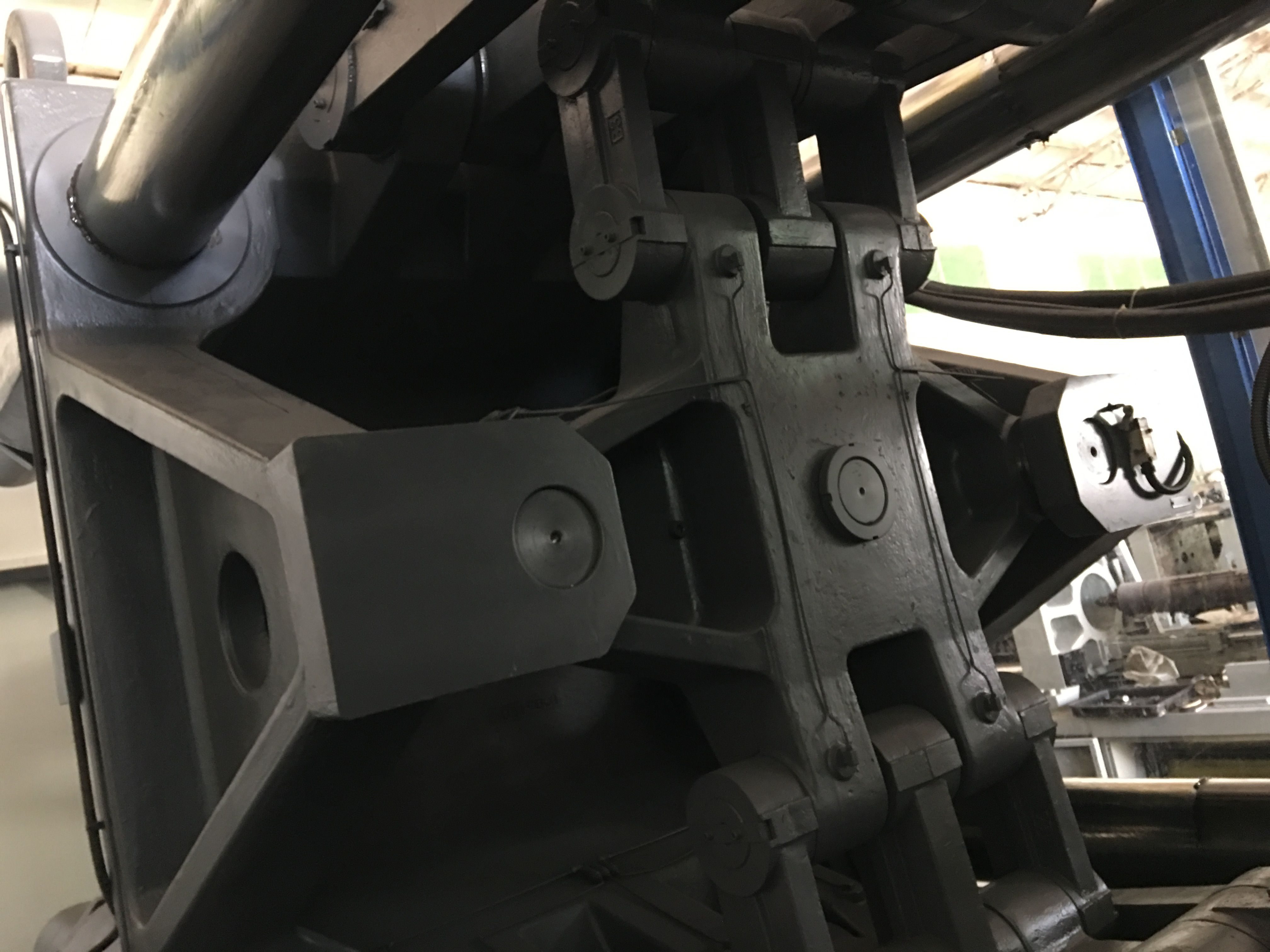

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

With our leading technology at the same time as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future alongside one another with your esteemed enterprise for Discount Price Haitian 1300t (servo) used Injection Molding Machine for Russia Importers, The product will supply to all over the world, such as: Munich , Belgium , United Arab Emirates , With the spirit of "credit first, development through innovation, sincere cooperation and joint growth", our company is striving to create a brilliant future with you, so as to become a most valuable platform for exporting our goods in China!

Visit "www.downloadshiva.com" for more Movies, videos & Documentries. Please Subscribe to the Channel if you like the post.

650 Ton Used Plastic Moulding Machine Sale In Delhi. Make - Hyundai

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.