Discount Price Niigata 180t used All-electric Injection Molding Machine for Argentina Importers

Discount Price Niigata 180t used All-electric Injection Molding Machine for Argentina Importers Detail:

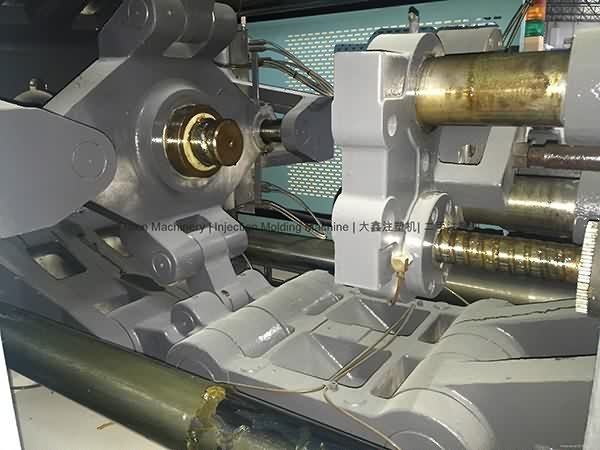

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

Plastic Injection Molding: Past, Present and Future

We stay with our company spirit of "Quality, Performance, Innovation and Integrity". We goal to create more value for our clients with our abundant resources, advanced machinery, experienced workers and superb solutions for Discount Price Niigata 180t used All-electric Injection Molding Machine for Argentina Importers, The product will supply to all over the world, such as: Haiti , Iran , Ukraine , Since our establishment, we keep on improving our products and customer service. We are able to provide you with a wide range of high quality hair products at competitive prices. Also we can produce different hair products according to your samples. We insist on high quality and reasonable price. Except this, we provide best OEM service. We warmly welcome OEM orders and customers all over the world to cooperate with us for mutual development in the future.

SOLD MACHINE

used Extrusion Blow Moulding Up to 1l Brand: MAGIC Model: MGL 2-3-D Year: 1999

https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300027131?opendocument&ln=en&origin=YouTube

Extrusión Soplado Hasta 1 l Usada Marca: MAGIC Modelo: MGL 2-3-D Año: 1999

Macchina Usata: Estrusione soffiagio fino 1lt

Beschreibung der Gebrauchtmaschine: Extrusionsblasformmaschine bis zu 1l

Description de la Machine d'occasion: Extrusion soufflage jusqu'à 1l

Használt gép: Extrudálás Fröccsöntés Blow Up a 1L

Б/У Оборудование:Экструзионно-выдувные машины 1л

Použitý Stroj: Extruze Vyfukovací tvarování až 1 litr

Maszyna używana: Wytłaczarka do 1 litra

Kullanılmış makine: 1 l kadar Ekstrüzyon Şişirme

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!