Discount Price Toshiba 1300t (wide platen) used Injection Molding Machine for UAE Manufacturer

Discount Price Toshiba 1300t (wide platen) used Injection Molding Machine for UAE Manufacturer Detail:

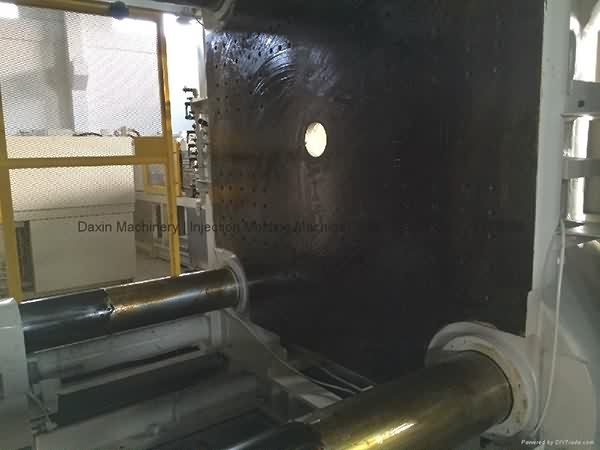

A Toshiba 1300t (wide platen) used injection molding machine for sale.

Model: IS1300DFW-200A.

Year of manufacture: 2004.

Screw diameter: 140mm.

Shot weight:9150g.

Tie bar spacing: 1430x1430mm.

Youtube video: https://youtu.be/hRc5cZvXlFs

Machine has wide platen, it is in good running condition. Interested customer is welcome to visit our warehouse to inspect and test run the machine.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

To meet the customers' over-expected pleasure , now we have our potent staff to offer our greatest general service which includes internet marketing, sales, planning, output, quality controlling, packing, warehousing and logistics for Discount Price Toshiba 1300t (wide platen) used Injection Molding Machine for UAE Manufacturer, The product will supply to all over the world, such as: Libya , Bogota , Rome , Since the establishment of our company, we've realized the importance of providing good quality goods and the best before-sales and after-sales services. Most problems between global suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question points they do not understand. We break down these barriers to ensure you get what you want to the level you expect, when you want it.

The Creation Station CNC Router Kickstarter Video

20,000Lb Used CAT Forklifts For Sale 616-200-4308 for more details go to https://d1a6prx2duc1gy.cloudfront.net/ or contact us at 616-200-4308. Inventory changes often, contact us for current inventory. Go here: https://d26fito5xtoopf.cloudfront.net We also buy and sell forklifts. Capacities from 15,000lb, 20,000lb, 30,000lb, 40,000lb, 60,000lb and 80,000lb for sale.

Used CAT, 20,000lb, Forklifts For Sale 616-200-4308

https://commondatastorage.googleapis.com/usedmachinery/used-large-capacity-forklifts-sale-fork-trucks/index.html

https://youtube.com/watch?v=XpUNcq2iMyI

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.