Discount wholesale Chuan Lih Fa CLF-950TX used Injection Molding Machine to Irish Manufacturer

Discount wholesale Chuan Lih Fa CLF-950TX used Injection Molding Machine to Irish Manufacturer Detail:

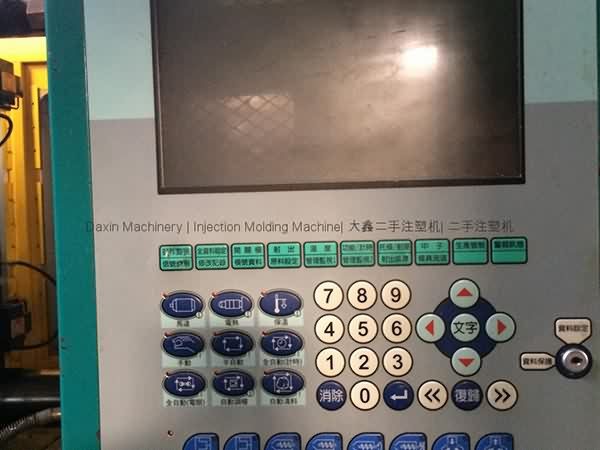

Chun Lih Fa CLF-950TX injection molding machine.

Year of manufacture: 2010.

Screw diameter: 80mm.

Tie bar spacing: 1120x1120mm.

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Making Plastic – Plastic Injection Moulding

abide by the contract", conforms on the market requirement, joins within the market competition by its superior quality likewise as provides far more comprehensive and great company for shoppers to let them develop into huge winner. The pursue on the corporation, is definitely the clients' gratification for Discount wholesale Chuan Lih Fa CLF-950TX used Injection Molding Machine to Irish Manufacturer, The product will supply to all over the world, such as: Greek , Brasilia , Manchester , Based on experienced engineers, all orders for drawing-based or sample-based processing are welcomed. We have now won a good reputation for outstanding customer service among our overseas customers. We will continue to try the best to supply you good quality products and solutions and the best service. We've been looking forward to serving you.

injection blow molding machine is ideal machine to produce bottles from 3ml to 1000ml small plastic hollow containers with HDPE,LDPE,PP,PS..... THE bottles ...

MMC Packaging can develop systems for after-moulding functions specific to your unique operation. Engineered for cost-effective efficiency, MMC equipment can assemble multiple-piece closures.

For more information, please contact us: consultmmc@mmcpackaging.com

www.mmcpackaging.com

Reasonable price, good attitude of consultation, finally we achieve a win-win situation,a happy cooperation!