Discount wholesale Sumitomo 130t All-Electric used Injection Molding Machine to Australia Importers

Discount wholesale Sumitomo 130t All-Electric used Injection Molding Machine to Australia Importers Detail:

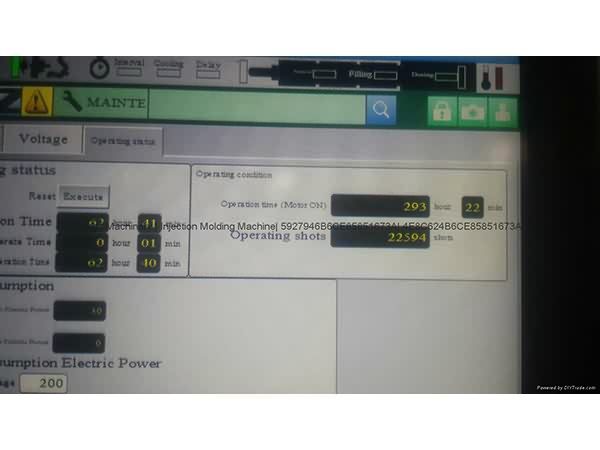

Sumitomo 130t All-Electric Used Injection Molding Machine Video: https://youtu.be/dh8sN_uCzjU Model: SE130EV-C360HP. Year: 2013. Screw diameter: 25/28mm. Injection Speed: 1000mm/s. Tie bar spacing: 510x510mm. 3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

Plastic Injection Molding: Past, Present and Future

Sticking to your belief of "Creating solutions of high quality and generating buddies with people from all around the world", we always put the fascination of customers to start with for Discount wholesale Sumitomo 130t All-Electric used Injection Molding Machine to Australia Importers, The product will supply to all over the world, such as: New Delhi , Paraguay , Cyprus , Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We now have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

Veja o estande da Toshiba Machine na feira K 2016 em Düsseldorf.

This video was uploaded from an Android phone.

This is a reputable company, they have a high level of business management, good quality product and service, every cooperation is assured and delighted!