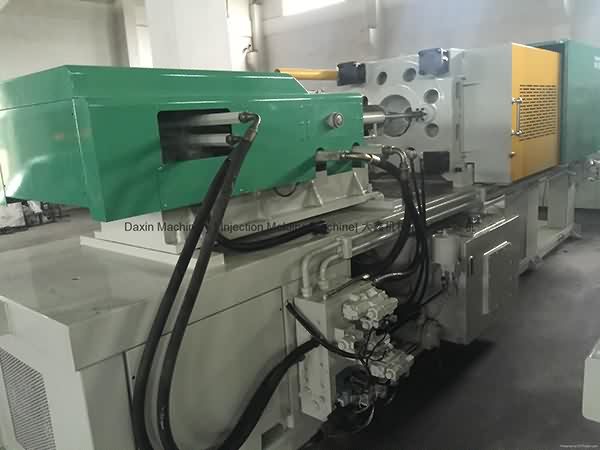

Discountable price Chen Hsong Super Master SM250TS used Injection Molding Machine for San Diego Factories

Discountable price Chen Hsong Super Master SM250TS used Injection Molding Machine for San Diego Factories Detail:

Taiwan Chen Hsong Super Master 250t used Injection Molding Machine for sale

Youtube Video: https://youtu.be/W0oWFc3ZjF4

Model: SM250TS.

Year: 2007..

Screw diameter: 45mm. .

Tie bar spacing: 620x620mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Emergence of Injection Molding in Plastic Industry

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most aggressive costs. So Profi Tools offer you finest benefit of money and we are ready to produce alongside one another with Discountable price Chen Hsong Super Master SM250TS used Injection Molding Machine for San Diego Factories, The product will supply to all over the world, such as: Germany , Moldova , El Salvador , We are always creating new technology to streamline the production, and provide goods with competitive prices and high quality! Customer satisfaction is our priority! You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

1. The products of IB-Series have smooth-even mouth, great sealing, round and smooth body and bottom, superior quality, and no seam mark. The machine is most suitable for manufacturing high quality products.

2. The mold design adopts the method of common mold base. Only by changing the mold parts, the product's shape, weight, or even the length can be changed. It saves time on mold alignment and doesn't require great expertise on mold changeover. Thus, it reduces the mold cost on manufacturing a wide range, but low volume of different applications.

3. The mechanical design is based on the blueprint of general-purpose injection molding machine. Hence, with general knowledge of injection molding machine, no matter machine operation or maintenance work can be handled with ease.

4. Applied materials include PC, PP, PE, PS, AS, PMMA, K-Resin, PET, PETG, TPR, PES, PCO and NYLON.

Mold-Masters Melt-CUBE Direct Side Gating Hot Runner System with TIM-Plastik Mold for Medical Injection Molding of a 20ml Syringe Barrel with Luer Lock -- as see live at ARBURG Technology Days in Loßburg, Germany (March 13-16, 2013)

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.