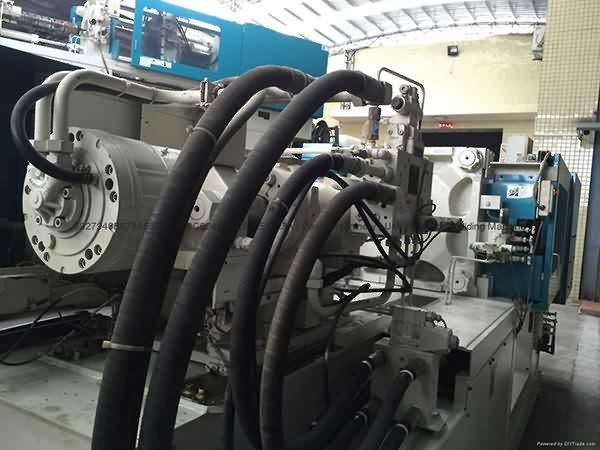

Europe style for Mitsubishi 160t used Injection Molding Machine to Oman Factory

Europe style for Mitsubishi 160t used Injection Molding Machine to Oman Factory Detail:

Mitsubishi 160t used Injection Molding Machines for sale.

Model: 160MSV.

Year: 2005.

Screw diameter: 45mm.

Tie bar spacing: 560m.

Very good running condition.

Interested customers can visit our warehouse to inspect the machine.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Plastic Injection Molding: Past, Present and Future

Adhering for the theory of "quality, services, performance and growth", we have received trusts and praises from domestic and worldwide shopper for Europe style for Mitsubishi 160t used Injection Molding Machine to Oman Factory, The product will supply to all over the world, such as: Portugal , Malaysia , Algeria , With the spirit of "credit first, development through innovation, sincere cooperation and joint growth", our company is striving to create a brilliant future with you, so as to become a most valuable platform for exporting our goods in China!

Video shows the process construction of the RTM Light mold the manufacture of the piece.

Produzido por Paulo Camatta, especialista em desenvolvimentos de processos como RTM Light, infusão convencional e com pele de silicone, laminação a vácuo e fabricação de modelos e moldes. Este vídeo foi desenvolvido baseado nos cursos de capacitação operacional que ministrava no CETECOM - Centro Tecnológico de Compósitos até Fevereiro de 2017, com o objetivo de disponibilizar inovações tecnológicas em processos de compósitos poliméricos termofixos.

Este vídeo demonstra resumidamente a contrução do molde e o processo RTM Light - Resin Transfer Moulding assistido a vácuo.

Atualmente Paulo Camatta é Diretor Executivo da CRC Composites, empresa de consultoria e Representação. www.crcomposites.com.br

WE ARE THE BEST PLASTIC MACHINE SUPPLIER: PET semi-automatic stretch blow molding machine Automatic stretch blow moulding machine ...

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!