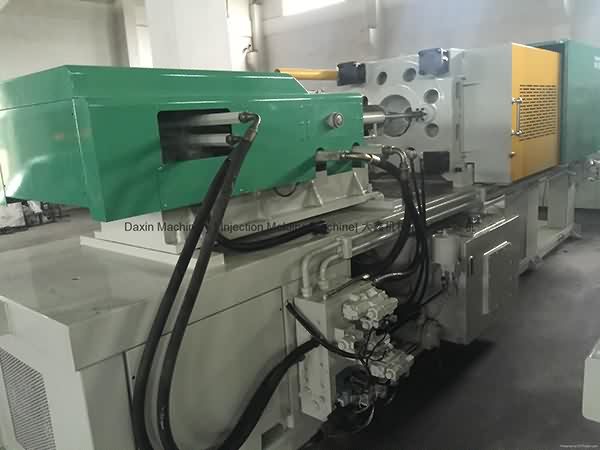

Excellent quality Chen Hsong Super Master SM250TS used Injection Molding Machine to Manufacturer

Excellent quality Chen Hsong Super Master SM250TS used Injection Molding Machine to Manufacturer Detail:

Taiwan Chen Hsong Super Master 250t used Injection Molding Machine for sale

Youtube Video: https://youtu.be/W0oWFc3ZjF4

Model: SM250TS.

Year: 2007..

Screw diameter: 45mm. .

Tie bar spacing: 620x620mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

We thinks what clients think, the urgency of urgency to act from the interests of a purchaser position of principle, allowing for greater top quality, decrease processing costs, price ranges are much more reasonable, won the new and aged prospects the support and affirmation for Excellent quality Chen Hsong Super Master SM250TS used Injection Molding Machine to Manufacturer, The product will supply to all over the world, such as: South Africa , Porto , Puerto Rico , Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

INJECTION MOULDING MACHINE FOR THERMOPLASTICS

PRESSE AD INIEZIONE PER TERMOPLASTICI

www.plasticmetal.it

Any questions,feel free to contact me.

Email:htpmachinery@gmail.com

Skype:zhang.tracy6

More information:https://twitter.com/htpmachinery

Chick here to subscribe us

https://www.youtube.com/channel/UCo4XjYB_mRONyQKah8jbjVw

Feature:

The plastic cup thermoforming machine can produce various kinds of throwaway plastic containers of cold drinks, yogurt, ice-cream, fast food, or instant noodle, as wells different kind of merchandise packages of medicine, toy, journal, textile and light industry, etc.

Thermoforming machine has two function:

1.Making round cups, and which can works all by itself. it combines the material feeding , heating, drawing, forming and cutting transporting into one process.

2. Making square cups and other shape cups which can be cutting with page. It combines the material feeding, heating. drawing, page cutting and transporting into one process.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.