Excellent quality Niigata 450t All-electric used Injection Molding Machine Supply to Finland

Excellent quality Niigata 450t All-electric used Injection Molding Machine Supply to Finland Detail:

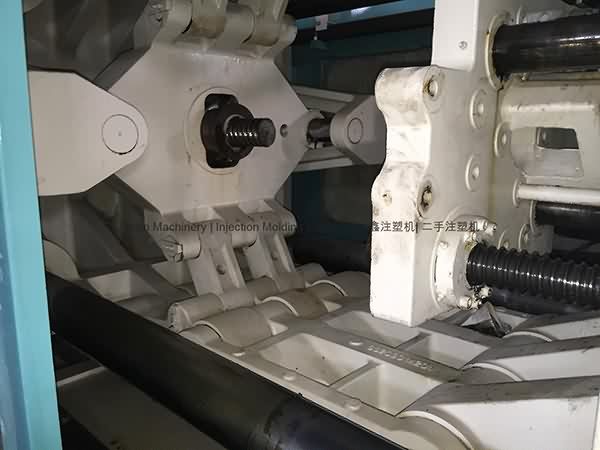

Niigata 450t All-Electric used Injection Molding Machine

Youtube Video: https://youtu.be/wHoMpY6lKng

Model: MD450S-IV.

Year: 2007.

Screw diameter: 82mm.

Tie bar spacing:820x820mm.

Injection Speed: 150mm/s.

Two units available. Interested customer is welcome to visit our warehouse to test machines running. Our warehouse is at Shenzhen, China (very near Hongkong and Guanzhou) .

Visit us after Chinaplas or Canton Fair!

Daxin Machinery

-Over 200 units of used injection molding machines in stock

-All can be inspected in the same warehouse under one roof

-All can be powered on for test-run in working condition

sales@daxin88.com / daxin88@hotmail.com

Skype: daxin-machinery / www.daxin88.com

Mobile: +8613509620296 (whatsapp) / +6596479097 (WeChat)

Follow Daxin Machinery: Facebook, Twitter, Google+, LinkedIn, Youtube.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

We provide fantastic energy in top quality and advancement,merchandising,gross sales and marketing and operation for Excellent quality Niigata 450t All-electric used Injection Molding Machine Supply to Finland, The product will supply to all over the world, such as: Iceland , United Arab Emirates , Jersey , They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to for you of fantastic good quality. Guided by the principle of "Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We are confident that we are going to have a bright prospect and to be distributed all over the world in the years to come.

https://www.gpmplas.com

mail:saldd@gpmplas.com

Phone:+86-13817552980

GPM MACHINERY (SHANGHAI) CO .,LTD.

Reed lee

GPM company(https://www.gpmplas.com) specializes in high quality plastic extrusion machine production , the company's technology from France .

WPC, namely WPC (Wood- Plastic Composites, WPC), is booming at home and abroad in recent years, a new class of composite materials, refers to the use of polyethylene, polypropylene and polyvinyl chloride, etc., instead of the usual resin adhesive, and more than 35% -70% wood flour, rice husk, straw and other waste plant fiber mixed into new wood materials, plastics processing and then by extrusion, molding, injection molding process to produce plates or profiles. Wood used in interior doors, baseboard, the whole cabinet, wardrobe, siding, ceiling, decorative wall panels, outdoor flooring, fence post, steel gazebo, garden fence, balcony rails, the fence around the garden, lounge chairs , tree pool, pergolas, flower boxes rack air conditioning, air conditioning shields, shutters, road badges, transport pallets, and so on.

https://www.AAdvantageLaundry.com.

Customer service staff and sales man are very patience and they all good at English, product's arrival is also very timely, a good supplier.