Factory best selling Hwa Chin 160t two-color used Injection Molding Machine to Slovak Republic Factory

Factory best selling Hwa Chin 160t two-color used Injection Molding Machine to Slovak Republic Factory Detail:

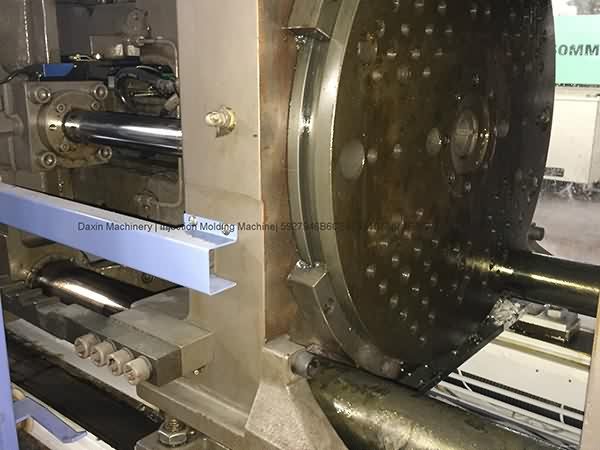

Taiwan Hwa Chin 160t Double Color used Injection Molding Machine.

Model: DC-160.

Year: 2010.

Screw diameters: 25/25mm.

Tie bar spacing: 450x450mm.

Diameter of rotary table: 600mm.

Very good running condition. Interested customer can visit our warehouse after Chinaplas to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

How Importers And Exporters Can Benefit From The Canton Fair

Assume full accountability to fulfill all demands of our purchasers; attain continual advancements by marketing the advancement of our clientele; grow to be the final permanent cooperative partner of purchasers and maximize the interests of purchasers for Factory best selling Hwa Chin 160t two-color used Injection Molding Machine to Slovak Republic Factory, The product will supply to all over the world, such as: Florida , Cyprus , Kyrgyzstan , Our staffs are adhering to the "Integrity-based and Interactive Development" spirit, and the tenet of "First-class Quality with Excellent Service". According to the needs of every customer, we provide customized & personalized services to help customers achieve their goals successfully. Welcome clients from home and abroad to call and inquire!

more information available: www.uniplastico.com

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.