Factory Cheap Haitian 120t used Injection Molding Machine for Afghanistan Manufacturers

Factory Cheap Haitian 120t used Injection Molding Machine for Afghanistan Manufacturers Detail:

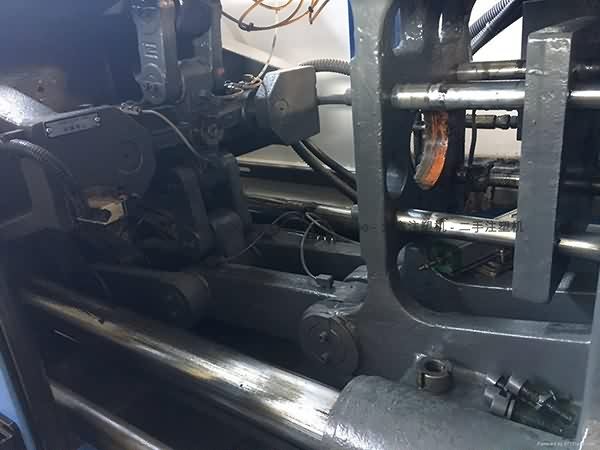

Haitian 120t used Injection Molding Machine

Model: SA1200/370.

Year: 2010.

Screw: A-D34.

Tie bar spacing: 410mm.

Two units. Very good working condition. Interested buyer can visit our warehouse to inspect them and test them running under power.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Precision of Plastic Machining

Being supported by an advanced and professional IT team, we could offer technical support on pre-sales & after-sales service for Factory Cheap Haitian 120t used Injection Molding Machine for Afghanistan Manufacturers, The product will supply to all over the world, such as: Nepal , El Salvador , Latvia , We've been adhering to the philosophy of "attracting customers with the best items and excellent service". We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

Chris Duke from Motorz TV https://www.motorz.tv shows you how to a nitrous oxide kit from Nitrous Express on a 2008 Ford Mustang GT (S197).

SUBSCRIBE FOR MORE: https://www.youtube.com/subscription_center?add_user=motorztv

Show notes: https://www.motorz.tv/nitrous-oxide/

Website: https://www.motorz.tv/

Facebook: https://www.facebook.com/motorztv

Twitter: https://twitter.com/motorz/

Welcome to Charmi Machinery Industries Pvt Ltd,

We are leading plastic machinery manufacturer based in Ahmedabad, Gujarat,

We Manufacture Horizontal Plastic Injection Molding Machine

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!