Factory Cheap Haitian 1300t (servo) used Injection Molding Machine to Macedonia Factories

Factory Cheap Haitian 1300t (servo) used Injection Molding Machine to Macedonia Factories Detail:

Haitian 1300t (servo) used Injection Molding Machine for sale.

Model: MA13000/10500

Year: 2012.

Tie bar spacing: 1250mm.

Still running production in factory. Good working condition.

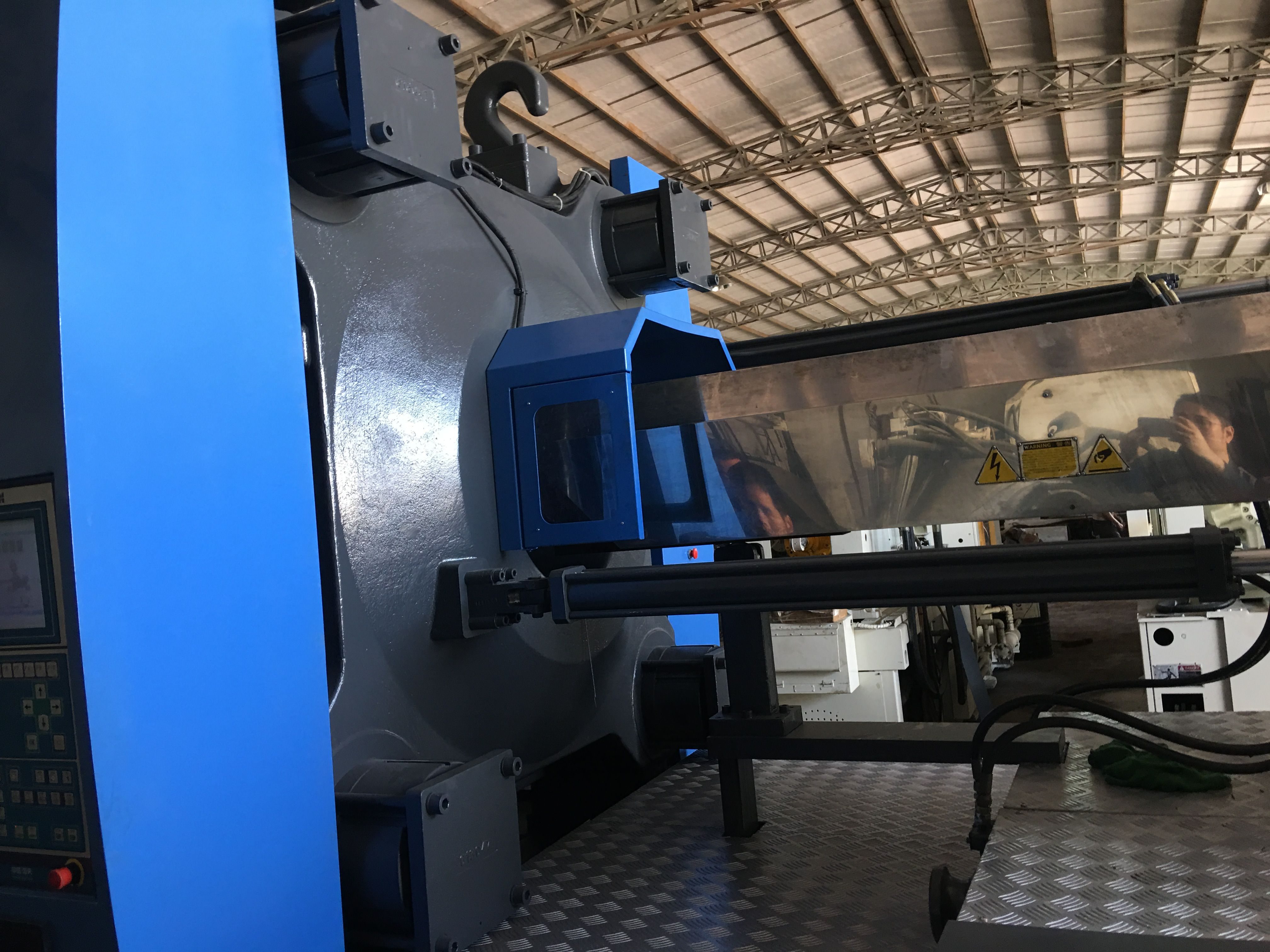

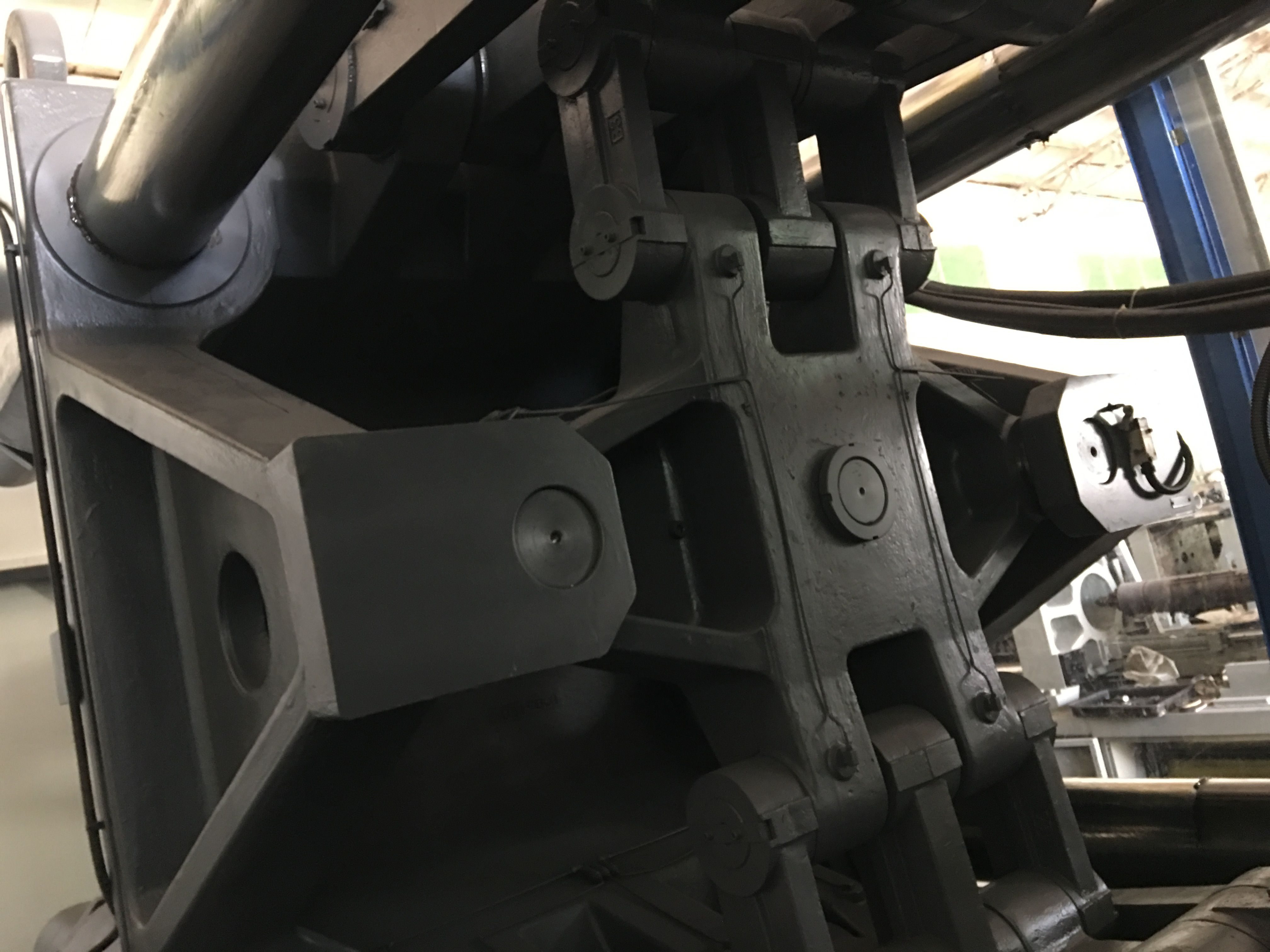

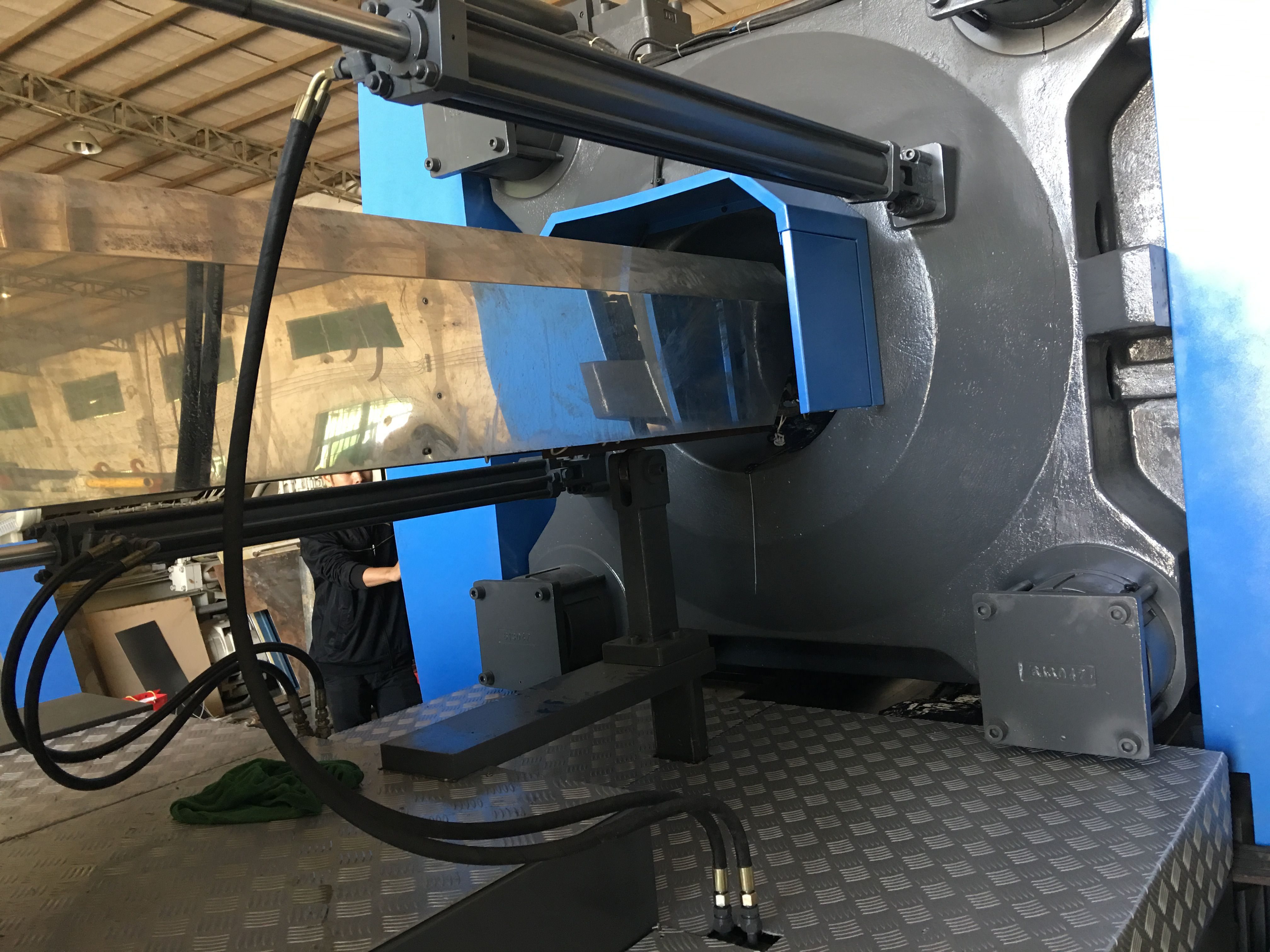

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Emergence of Injection Molding in Plastic Industry

To be able to give you benefit and enlarge our business, we also have inspectors in QC Team and assure you our greatest service and products for Factory Cheap Haitian 1300t (servo) used Injection Molding Machine to Macedonia Factories, The product will supply to all over the world, such as: Ghana , Comoros , Turkey , Our mission is "Provide Products with Reliable Quality and Reasonable Prices". We welcome customers from every corner of the world to contact us for future business relationships and achieving mutual success!

Plastic Injection Molding Machine-SH KC 200M8-SH 2014 export Algeria.

Click below and get a wide information about this Used Machine: https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300035192?

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,