Factory Cheap Haitian 160t used Injection Molding Machine to America Factory

Factory Cheap Haitian 160t used Injection Molding Machine to America Factory Detail:

Haitian 160t used plastic injection molding machine.

Model: SA1600/540v.

Year: 2006.

Tie bar spacing: 465x465mm.

Screw diameter: 38mm.

Screw type: B-D38.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

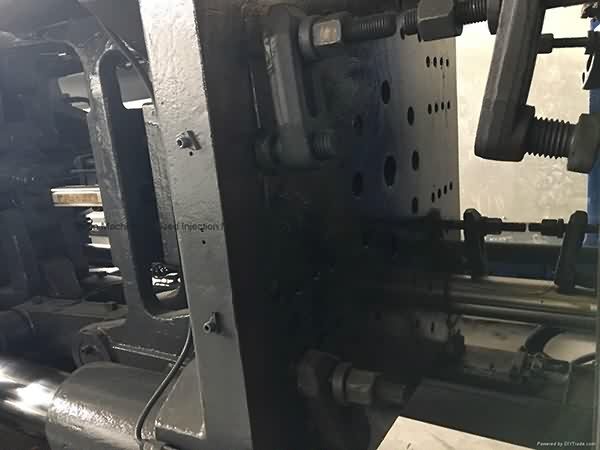

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Emergence of Injection Molding in Plastic Industry

We will devote ourselves to giving our esteemed buyers using the most enthusiastically thoughtful services for Factory Cheap Haitian 160t used Injection Molding Machine to America Factory, The product will supply to all over the world, such as: Bahamas , Philadelphia , Suriname , We have now 48 provincial agencies in the country. We also have stable cooperation with several international trading companies. They place order with us and export solutions to other countries. We expect to cooperate with you to develop a larger market.

SUPPORT FREE ENERGY USE THIS LINK# seo MUST SEE VIDEOS TOP 12 free energy https://www.gofundme.com/hutchison-effect-energy i upload videos ...

We RAG INNOVATIONS are the most innovative and most updated Low-Cost Sanitary Napkin machine manufacturer in India.We are providing facility to customize the machine as according to your valuable requirements. We are committed to providing you not only best machinery but also provide you the most recent updates in the field of LOW-COST SANITARY NAPKIN.We also committed to providing you the best quality raw material, which will help you not only making your manufacturing cost most economical but also improving your production rate.

email id : raginnovations@gmail.com

phone no. 07512461973

VIRAG: +919425128596

ANURAG: +919425781445

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.