Factory Cheap JSWJ280EIII used Injection Molding Machine for Bangladesh Importers

Factory Cheap JSWJ280EIII used Injection Molding Machine for Bangladesh Importers Detail:

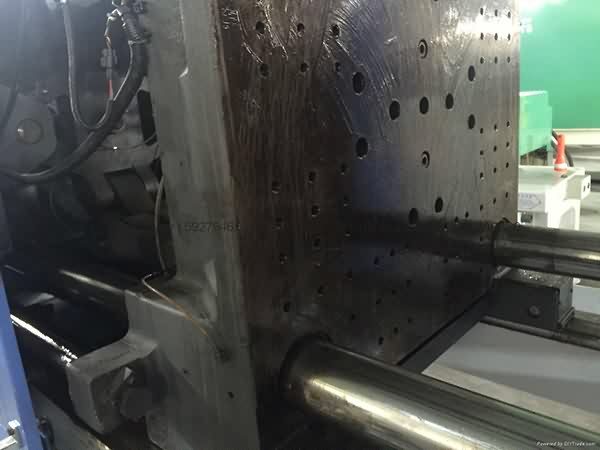

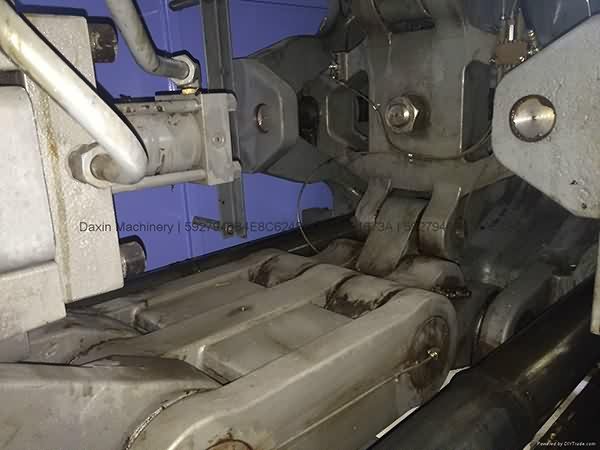

JSWJ280EIII used Injection Molding Machine for sale.

Model: J280EIII.

Year : 2005.

Tie bar spacing: 630x630mm.

Screw diameter: 53mm.

Injection Volume: 463cm^3.

Video: https://youtu.be/eaAHtdSJ9GQ

Good running condition. Interested customer is welcome to visit our warehouse to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

How Importers And Exporters Can Benefit From The Canton Fair

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for Factory Cheap JSWJ280EIII used Injection Molding Machine for Bangladesh Importers, The product will supply to all over the world, such as: India , Netherlands , Southampton , In order to make more people know our products and to enlarge our market, we have devoted a lot of attention to technical innovations and improvement, as well as replacement of equipment. Last but not the least, we also pay more attention to training our managerial personnel, technicians and workers in planned way.

Machine knobs are often required for shop jigs and are expensive if bought or the size is not available. So make your own knurled knob from a bottle cap, a hex ...

powder machinery for plastic bag filling sealing packer machine, plastic film roll forming packing bag machine,Free Shipping lost weight coffee packing machine for standard need, Fine Powder Filling Machine Powder Packing Machine,0-100g Full automatic vertical packing machine, free for spare parts,Medicine packaging machines, powder pouch packaging machinery, powder packing machine,300-500g powder bag filling and packing machine with auger filler,free shipment 0-200ml Ice pop/jelly/Liquid soft drink stick bag filling sealing and packaging machine,0-100g Fully Automatic Powder Packing Machine with volumetric cup filler,3 side seal or 4 side seal,10-1000g baggging scale machine, automatic filling machine, auto weigher,Washing powder / powder /floue filling maching,Single Tube Vertical Form/Fill/Seal Machine,tea bag packing machine,packaging material,5-250g Free Shipping lost weight packing machine filling and sealing machine good quality with best price,Automatic Vertical Solid Granules Powder Food Filling Sealig packaging machine manufactorers Bag Volumetric Filling Machine,0-1kg Food/cake/biscuit /bread/bakery/snack packing machine,factory price,today machine,semi auto powder packing machine with auger filler,Well selling and reasonable price andautomatic milk powder,sugar packing machine with one year guarantee,Full automatic medical powder packing machine full automatic packing machine for powder good quality wtih best price,Full Automatic Liquid Filling Machine Free Shipping,100-200g coffee packing machine filling and sealing machine good quality with best price,100-500ml Automatic juice sachet/bags/pouch packing machine,100-1000ml Factory price juice bag packing machine, for oversea agency,paint machine,stainless steel vertical packaging machine, new model, stronger qualityBest selling high quality granule plastic bag packing machine for powder products,500-100g millet, coix seed, rice granule packing machine/quantitative packaging machine,Automatic Vertical Form Fill Seal Small Sachet Power Granules Packaging Machine for coffee/candy/medical pills/plant seeds,200-500ml Automatic liquid bag packaging machine packaging of milk soy sauce bag packing machine bag milk packaging machine,mini pack filling machine,small scale spices powder packing machine for small business,Manual Edible Oil Filling Machine,Edible Oil Packing Machine for Olive, Vegetable ,Cooking Oil,automatic film impulse sealer Heat plastic bag Sealer, sealing machine, suitable for heat packing,Sugar, coffee packaging machine,large volume skimmed powder packing machine for foreign countries in reasonable quotation,mineral water plastic bag filling and sealing small size semi packing machine with ate printing,50-100ml liquid bag packing machine for ketchup/shampoo/sauce,sachet water filling machine,0-250ml Ice pop/jelly/Liquid soft drink stick bag filling sealing and packaging machine,Free Shipping coffee packing machine food packing bag packing equipment,3-30g soy / sesame paste,420K Automatic vertical large particle packing machine,free shipment 100-1000ml Factory price juice bag packing machine, for oversea agency,paint machine,Instant noodles Ingredients automatic packaging machines,soil filling machine with measuring cups for bottle/bag/pouch, section payment,Tea / milk / milk packaging sides sealed screw

Problems can be quickly and effectively resolved, it is worth to be trust and working together.