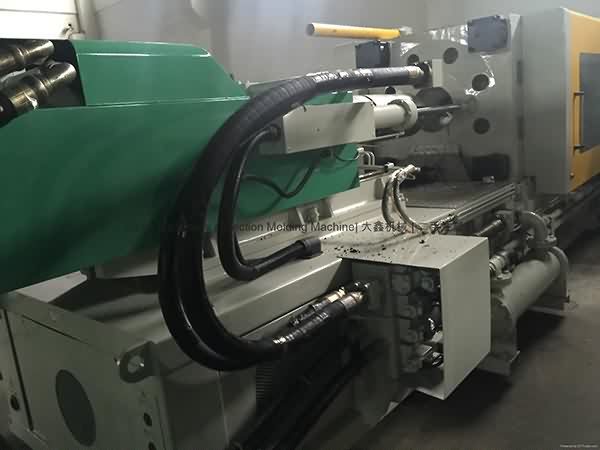

factory customized Chen Hsong Super Master SM450TS used Injection Molding Machine Wholesale to Roman

factory customized Chen Hsong Super Master SM450TS used Injection Molding Machine Wholesale to Roman Detail:

Taiwan Chen Hsong Super Master 450t used Injection Molding Machine

Video: https://youtu.be/lo5SPPvPMCo

Model: SM450TS.

Year 2009.

Screw diameter: 60mm.

Tie bar spacing: 820x820mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

We'll make each hard work to become excellent and excellent, and speed up our measures for standing from the rank of intercontinental top-grade and high-tech enterprises for factory customized Chen Hsong Super Master SM450TS used Injection Molding Machine Wholesale to Roman, The product will supply to all over the world, such as: Mali , Zimbabwe , Georgia , Upon today, we've customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We've been looking forward to doing business with you.

High speed toothbrush making machine(Two color) with high quality and best price.

Cincinnati Milacron VT110 Used Injection Molding Machine, 110 US ton, Yr. 1999, 10 oz., ZAG #7496.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!