factory customized JSWJ280EIII used Injection Molding Machine Supply to Sacramento

factory customized JSWJ280EIII used Injection Molding Machine Supply to Sacramento Detail:

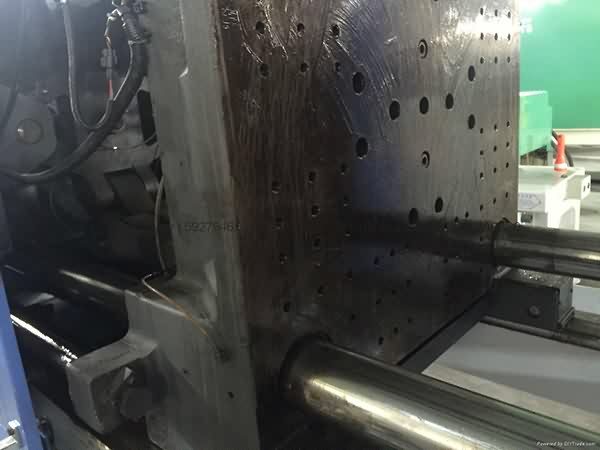

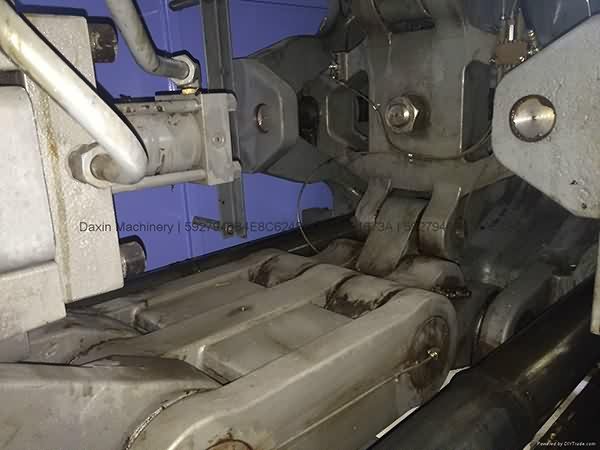

JSWJ280EIII used Injection Molding Machine for sale.

Model: J280EIII.

Year : 2005.

Tie bar spacing: 630x630mm.

Screw diameter: 53mm.

Injection Volume: 463cm^3.

Video: https://youtu.be/eaAHtdSJ9GQ

Good running condition. Interested customer is welcome to visit our warehouse to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

Our concentrate on is always to consolidate and enhance the excellent and service of present solutions, in the meantime regularly develop new products to meet distinctive customers' demands for factory customized JSWJ280EIII used Injection Molding Machine Supply to Sacramento, The product will supply to all over the world, such as: Spain , Sao Paulo , Algeria , Our Company has qualified engineers and technical staff to answer your questions about maintenance problems, some common failure. Our product quality assurance, price concessions, any questions about the items, Be sure to feel free to contact us.

027-87514692/武汉丽晶电子/744271986@qq.com/LMG5278XUFC-00T,Hitachi 9.4inch Injection molding machine LCD Panel; More models LCD panel, please ...

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.