factory customized Toshiba IS650GT Used Injection Molding Machine to Brasilia Manufacturer

factory customized Toshiba IS650GT Used Injection Molding Machine to Brasilia Manufacturer Detail:

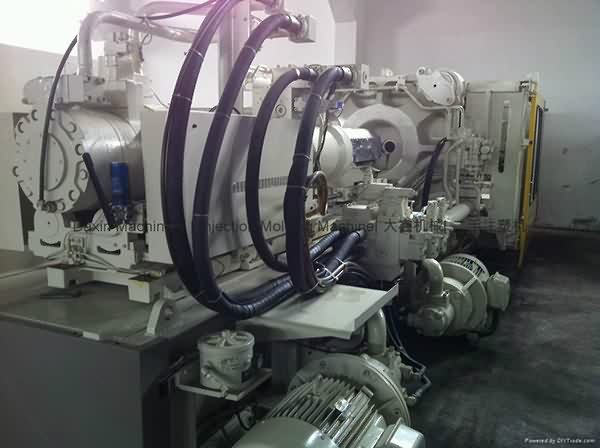

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT-59A.

Screw diameter: 90/95mm.

Tie bar spacing: 980x980mm.

Year: 2004/2006.

Controller type: V10.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

Making Plastic – Plastic Injection Moulding

We'll make every effort and hard work to be superb and excellent, and speed up our steps for standing inside the rank of intercontinental top-grade and high-tech enterprises for factory customized Toshiba IS650GT Used Injection Molding Machine to Brasilia Manufacturer, The product will supply to all over the world, such as: Auckland , UK , Plymouth , Business philosophy: Take the customer as the Center, take the quality as the life, integrity, responsibility, focus, innovation.We will provide professional, quality in return for the trust of customers, with most major global suppliers,all of our employees will work together and move forward together.

樺欽HC-280四缸/柱內560/1997年/曲手+模板104年有全新整修/盟立電腦/目前做PC塑料.

this machine manufactured by ningbo ITC equipment, TEL: +86-13 777 00 4313(whatsapp/wechat), EMAIL: tradeningbo@foxmail.com, WEB: www.yidexi.cn

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.