Factory directly JSWJ280EIII used Injection Molding Machine for Macedonia Factory

Factory directly JSWJ280EIII used Injection Molding Machine for Macedonia Factory Detail:

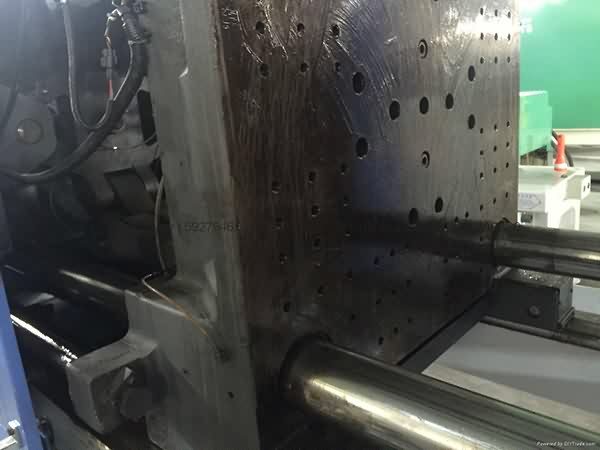

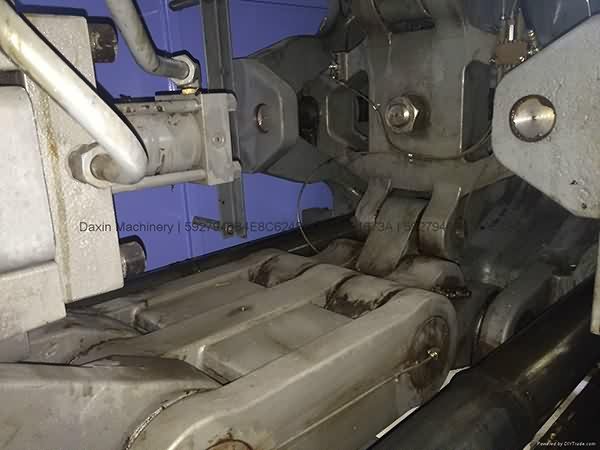

JSWJ280EIII used Injection Molding Machine for sale.

Model: J280EIII.

Year : 2005.

Tie bar spacing: 630x630mm.

Screw diameter: 53mm.

Injection Volume: 463cm^3.

Video: https://youtu.be/eaAHtdSJ9GQ

Good running condition. Interested customer is welcome to visit our warehouse to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Making Plastic – Plastic Injection Moulding

Adhering into the basic principle of "quality, assistance, effectiveness and growth", we have attained trusts and praises from domestic and worldwide client for Factory directly JSWJ280EIII used Injection Molding Machine for Macedonia Factory, The product will supply to all over the world, such as: Egypt , Somalia , Plymouth , We have our own registered brand and our company is developing rapidly owing to high quality products, competitive price and excellent service. We sincerely hope to establish business relations with more friends from home and abroad in the near future. We look forward to your correspondence.

During the 1980's the plastic making industry in Taiwan began to take off with many companies subcontracting their operations to Taiwanese suppliers. Through ...

20,000Lb Used Taylor Forklifts For Sale 616-200-4308 for more information go to https://d1a6prx2duc1gy.cloudfront.net/ or phone us at (616) 200-4308. Available Forklifts changes often, contact us for most recent inventory. Go here: https://d26fito5xtoopf.cloudfront.net We also buy and sell forklifts. Capacities from 15,000lb to 100,000lb for sale.

Used Taylor, 20,000lb, Forklifts For Sale 616-200-4308

https://commondatastorage.googleapis.com/usedmachinery/used-large-capacity-forklifts-sale-fork-trucks/index.html

Products and services are very good, our leader is very satisfied with this procurement, it is better than we expected,