Factory directly supply Mitsubishi 1300t Used Injection Molding Machine to South Africa Manufacturers

Factory directly supply Mitsubishi 1300t Used Injection Molding Machine to South Africa Manufacturers Detail:

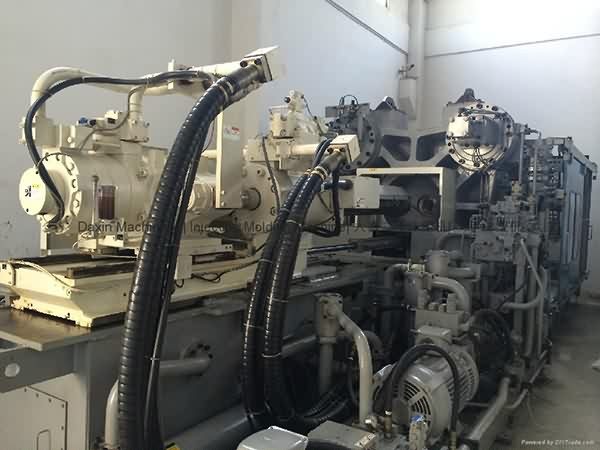

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Screw diameter: 100mm.

Injection volume: 4540cm^3.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Plastic Injection Molding: Past, Present and Future

Bear "Customer first, High quality first" in mind, we perform closely with our consumers and provide them with efficient and experienced services for Factory directly supply Mitsubishi 1300t Used Injection Molding Machine to South Africa Manufacturers, The product will supply to all over the world, such as: Kazakhstan , Zurich , Bandung , It is our customers' satisfaction over our products and services that always inspires us to do better in this business. We build mutually beneficial relationship with our clients by giving them large selection of premium car parts at marked down prices. We provide wholesale prices on all our quality parts so you are guaranteed greater savings.

CINCINNATI MILACRON 220-TON PLASTIC INJECTION MOLDING MACHINE, MODEL VT-220-20, 17 OZ (482 GRAMS), 1990, CAMAC XTL CONTROLS, 21.3" ...

Simufact, sayısal simülasyon yazılımı geliştirme konusunda sektörün en büyük firması olan MSC Software grubu içerisinde yer almaktadır ve geliştirdiği Simufact Forming, Simufact Welding ve Simufact Additive programları ile soğuk, ılık ve sıcak dövme, kütlesel ve sac metal şekillendirme, profil ve yüzük haddeleme, mekanik birleştirme, ısıl işlem; ark, lazer ve punta kaynağı ile eklemeli üretim prosesleri hızlı ve doğru şekilde bilgisayar ortamında analiz edilebilmektedir.

Ayrıltılı bilgi için internet sayfamızı ziyaret edebilirsiniz.

https://www.netformmetal.com

NETFORM Mühendislik Makina Metal

Goods just received, we are very satisfied, a very good supplier, hope to make persistent efforts to do better.