Factory directly supply Niigata 180t used All-electric Injection Molding Machine – CLF Injection Molding Machine

Factory directly supply Niigata 180t used All-electric Injection Molding Machine – CLF Injection Molding Machine Detail:

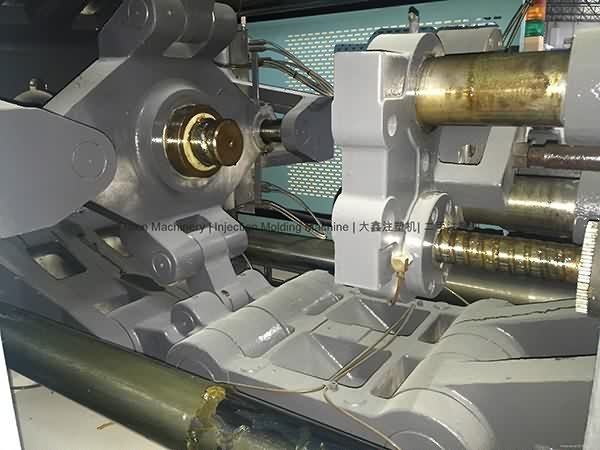

Niigata 180t All-electric used Injection Molding Machine

Youtube Video: https://youtu.be/gdXRtoSqbW0

Model: MD180S-IV.

Year: 2006.

Injection Speed: 300mm/s.

Screw diameter: 35mm.

Tie bar spacing: 510x510mm.

Machines are in good running condition. Two units available. Interested customers are welcome to visit our warehouse to inspect and test machines running.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

To be a result of ours specialty and service consciousness, our enterprise has won an excellent status between buyers all around the globe for Factory directly supply Niigata 180t used All-electric Injection Molding Machine – CLF Injection Molding Machine, The product will supply to all over the world, such as: Curacao , Bolivia , Chile , Welcome to visit our company, factory and our showroom where displays various products that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to provide you the best service. Please contact us if you need more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

Plastic preform injection moulding machine.

Applicaiton of Manual mold silicone:

Manual mold silicone rubber is mainly used for model design of manual mold, PVC plastic mold, cement products, low melting point ally toy molds, alloy toy, plastic toys, electronics, handicrafts, stationery, large-scale sculpture, reproduction of culture relic, shoe sole molds, pad printing allocation, Electronic equipment antivibration and so on.

Contact: Ms Vicky (林苑如)

Tel: 0086-755-89948013

Fax: 0086-755-89948030

Mob: 0086-13751020433

E-mail: hyz@szrl.net

QQ: 379973354

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly