Factory For JSWJ1300EIII used Injection Molding Machine Export to Greece

Factory For JSWJ1300EIII used Injection Molding Machine Export to Greece Detail:

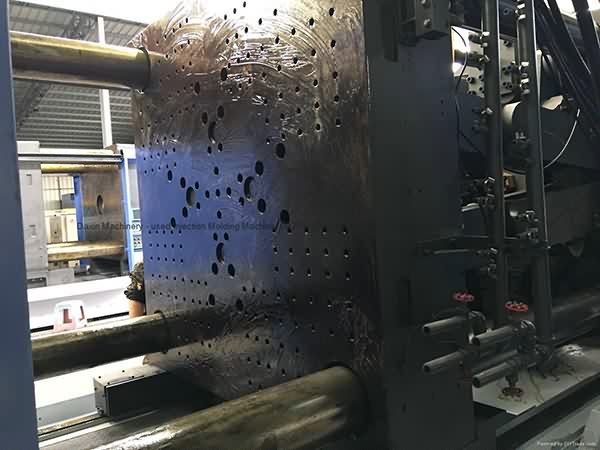

JSW 1600t used injection molding machine.

Model: J1300EIII.

Year: 2008.

Tie bar spacing: 1315x1270mm.

Screw diameter: 120mm.

Machine is in good working condition. Interested customer can visit our warehouse to inspect the machine and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

How Importers And Exporters Can Benefit From The Canton Fair

While using the "Client-Oriented" organization philosophy, a rigorous top quality command process, highly developed production devices and a potent R&D workforce, we normally provide high quality products, outstanding solutions and aggressive charges for Factory For JSWJ1300EIII used Injection Molding Machine Export to Greece, The product will supply to all over the world, such as: European , Sri Lanka , Riyadh , We set a strict quality control system. We have return and exchange policy, and you can exchange within 7 days after receive the wigs if it is in new station and we service repairing free for our products. Please feel free to contact us for further information if you have any questions. We are glad to work for every client.

Click below and get a wide information about this Used Machine: https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300034828?

Gelong industries

www.gelongindustries.com

Manufactures & Traders of-DALL, BESAN, FLOUR MILL MACHINERY.

A 15 vikas vihar, chander vihar, nilothi ext. Part 3. New Delhi

Mobile number 09911401311, 09868241884, 8800341233

For videos type (gelong.in)in YouTube

Email address :- gelongindustries@gmail.com

small besan plant

raw material for besan plant

mini besan plant project report

besan plant video

mini besan mill project report

besan pulverizer

rajdhani besan plant

besan manufacturers in indore

besan manufacturing process

price of besan per kg

besan wholesale price

besan mill plant cost

rajdhani besan 1kg price

dal mill plant in india

dal mill process

dal mill business

rice mill

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!