factory low price Chen Hsong Super Master SM50 used Injection Molding Machine for Cyprus Importers

factory low price Chen Hsong Super Master SM50 used Injection Molding Machine for Cyprus Importers Detail:

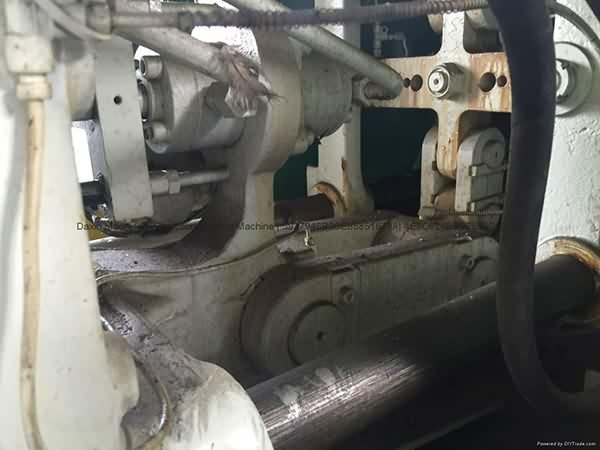

Chen Hsong Super Master 50t Used Injection Molding Machine.

Model: SM50T.

Year: 2004.

Screw diameter: 24mm.

Tie bar spacing: 310x310mm.

Controller: 2000.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

Bear "Customer first, High quality first" in mind, we perform closely with our consumers and provide them with efficient and experienced services for factory low price Chen Hsong Super Master SM50 used Injection Molding Machine for Cyprus Importers, The product will supply to all over the world, such as: New Zealand , Sweden , Boston , We hope we can establish long-term cooperation with all of the customers, and hope we can improve competitiveness and achieve the win-win situation together with the customers. We sincerely welcome the customers from all over the world to contact us for anything you need to have!Welcome all customers both at home and abroad to visit our factory. We hope to have win-win business relationships with you, and create a better tomorrow.

Good day! Hope you'll have a nice whole day! We're the factory of making beverage processing, filling and packing machines for different type of containers, like ...

Techspan New Zealand have represnted ENGEL since 1979 -

In this video - ENGEL easix - the multifunctional 6-axis robot

Working with ease in all three dimensions: The ENGEL easix six-axis robot and its integrated control unit are ideally equipped for current and future tasks, making your production even more efficient. No matter whether you need a particularly flexible automation solution or face special requirements, such as cleanroom production.

Further information: https://www.techspan.co.nz/engel/

This supplier offers high quality but low price products, it is really a nice manufacturer and business partner.