factory low price JSWJ150EIII used Injection Molding Machine to Guatemala Manufacturers

factory low price JSWJ150EIII used Injection Molding Machine to Guatemala Manufacturers Detail:

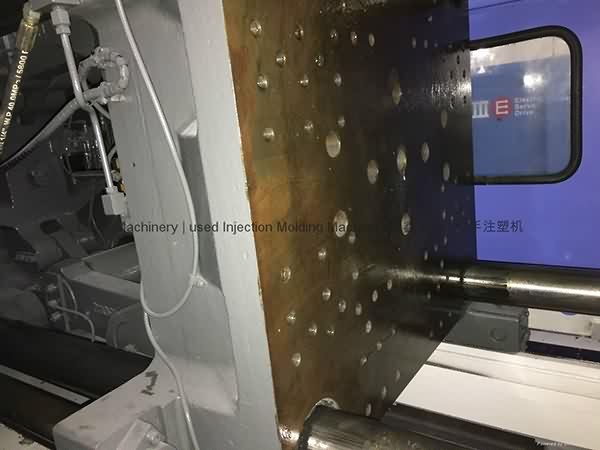

JSWJ150EII used Injection Molding Machine.

Model: JSWJ150EIII.

Year: 2006.

Screw diameter: 46mm.

Tie bar spacing: 510x510mm.

Machine is in very good running condition. Interested customer please visit our warehouse to inspect the machine and test it running under power.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

We're committed to furnishing easy,time-saving and money-saving one-stop purchasing support of consumer for factory low price JSWJ150EIII used Injection Molding Machine to Guatemala Manufacturers, The product will supply to all over the world, such as: Lithuania , Stuttgart , Brunei , We look forward to hearing from you, whether you are a returning customer or a new one. We hope you will find what you are looking for here, if not, please contact us immediately. We pride ourselves on top notch customer service and response. Thank you for your business and support!

ENGEL clearmelt technolgy. A thin layer of PUR is injected in the mold to cover the plastic part and to give high gloss and anti scratch properties to the molded ...

Call: 888-803-3412 Used Plastic Machinery For Sale In Pakistan From Plastic Machinery & Parts Searching for used plastic machinery for sale in Pakistan?

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!