factory low price Toshiba IS650GT Used Injection Molding Machine Export to Roman

factory low price Toshiba IS650GT Used Injection Molding Machine Export to Roman Detail:

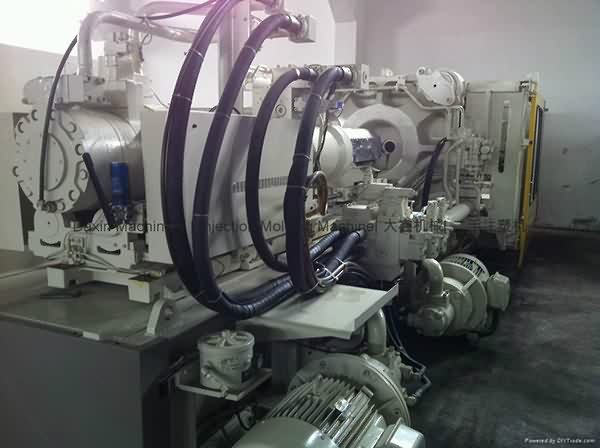

Toshiba 650t used Injection Molding Machine.

Video: https://youtu.be/60tsjjKGmX8

Model: IS650GT-59A.

Screw diameter: 90/95mm.

Tie bar spacing: 980x980mm.

Year: 2004/2006.

Controller type: V10.

Machines are in good working condition. A few units available. Our warehouse is located at ShenZhen of China, very near HongKong and GuangZhou. Interested buyer is welcome to visit our warehouse during Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

Our purpose is to fulfill our clients by offering golden company, great price and premium quality for factory low price Toshiba IS650GT Used Injection Molding Machine Export to Roman, The product will supply to all over the world, such as: Philippines , Ireland , Milan , Profession, Devoting are always fundamental to our mission. We have always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

Plastic scrap - Briquette press machine test.

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!