Factory made hot-sale Chen Hsong Super Master SM450TS used Injection Molding Machine Supply to Belarus

Factory made hot-sale Chen Hsong Super Master SM450TS used Injection Molding Machine Supply to Belarus Detail:

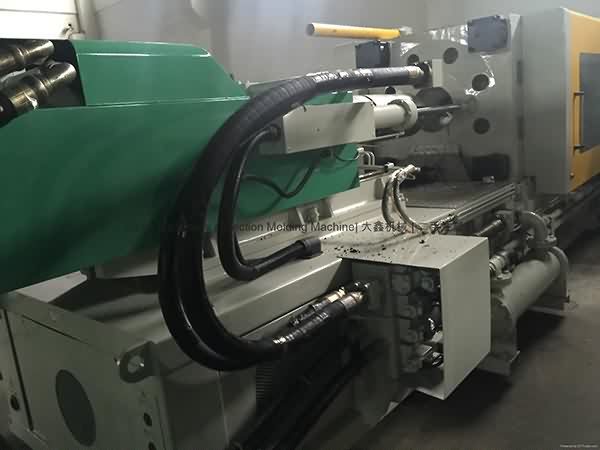

Taiwan Chen Hsong Super Master 450t used Injection Molding Machine

Video: https://youtu.be/lo5SPPvPMCo

Model: SM450TS.

Year 2009.

Screw diameter: 60mm.

Tie bar spacing: 820x820mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

The Emergence of Injection Molding in Plastic Industry

Fast and fantastic quotations, informed advisers to help you choose the correct products that suits all your needs, a short manufacturing time, responsible good quality control and distinct companies for paying and shipping affairs for Factory made hot-sale Chen Hsong Super Master SM450TS used Injection Molding Machine Supply to Belarus, The product will supply to all over the world, such as: Latvia , Peru , Guatemala , "Create Values,Serving Customer!" is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, You should contact with us now!

This video is taken in Chinaplas2016 Shanghai. Machine in the video is our latest model: HFTF-80T which is designed special for high yield production need with forming area of 762*470mm. Sample cup in the video is pet material with 92.5mm diameter.

APPLICATION:

HFTF-80T-H Automatic Thermoforming Machine suitable for PP, HIPS, PVC , PET,ETC. sheet.

Main Technical Specification

1- Max. Forming Area 762×470mm

2- Max. Forming Depth 180mm

3-Clamping Force 650KN

4- Max Sheet Width Range 820mm

5- Sheet Thickness 0.4-2.5mm

6- Air Pressure 0.7-0.85mpa

7- Water Consumption 50L/min

8- Air Consumption 5000L/min

9- Max.No-load Speed 42 Cycles/min

10- Power (Three Phase Four Wire) 3×380V+N+PE.50HZ

11- Heating Power 150kw

12- Main Motor Power 15kw

13- Stretch Motor Power 15kw

14- Feeding Motor Power 5.5kw

15- Machine Weight 15500kg

16- Dimension 13000×4500×3800mm

MISSION: HOGA CLEAN INDIA

Through Swachh Bharat Recycle machine

one aims to become a Global Corporate

Citizen, committed to recycling every PET

bottle that is thrown into waste.

These machines have been designed to

dispose and recover products effectively and

are used for cost effective means for

recycling and disposal of waste.

Product variety is complete, good quality and inexpensive, the delivery is fast and transport is security, very good, we are happy to cooperate with a reputable company!