Factory made hot-sale CLF-1000T (servo) used Injection Molding Machine to kazakhstan Factories

Factory made hot-sale CLF-1000T (servo) used Injection Molding Machine to kazakhstan Factories Detail:

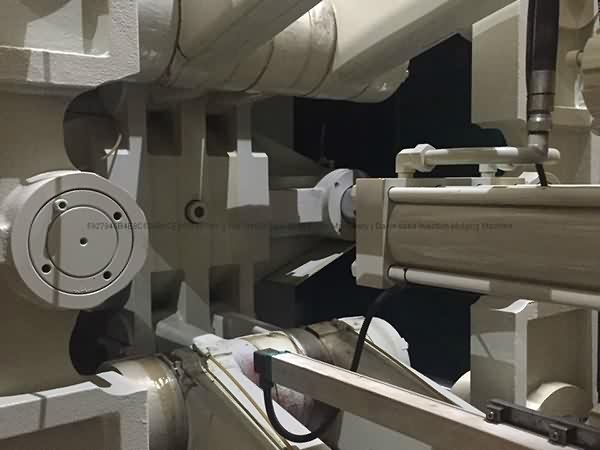

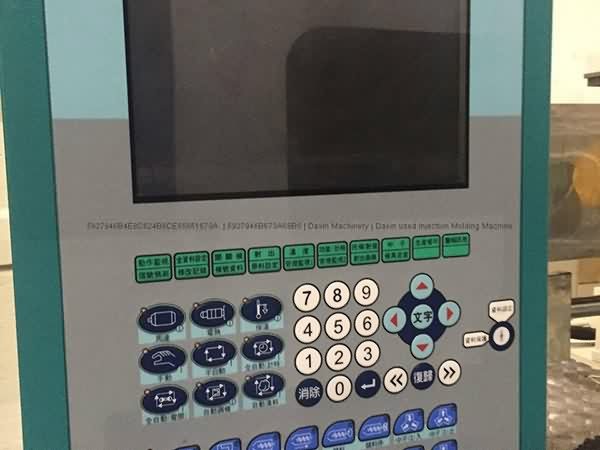

CLF-1000T (servo) used Injection Molding Machine.

Model: CLF-1000T.

Year: 2011.

Screw diameter: 105mm.

Tie bar spacing: 1060mm.

Very good working condition. Interested customer pls visit our warehouse to inspect the machine and test it running under power..

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

How Importers And Exporters Can Benefit From The Canton Fair

Persisting in "High good quality, Prompt Delivery, Aggressive Price", we've established long-term cooperation with shoppers from each overseas and domestically and get new and previous clients' high comments for Factory made hot-sale CLF-1000T (servo) used Injection Molding Machine to kazakhstan Factories, The product will supply to all over the world, such as: Jordan , Puerto Rico , Palestine , Our company has already had a lot of top factories and qualified technology teams in China, offering the best goods, techniques and services to worldwide customers. Honesty is our principle, skilled operation is our work, service is our goal, and customers' satisfaction is our future!

MS-1200 Fully Automatic Blow Moulding Machine from PanAsia Exports, China.

This video was uploaded from an Android phone.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.