Factory made hot-sale Haitian 1300t (servo) used Injection Molding Machine – Toshiba Plastic Injection Molding Machine

Factory made hot-sale Haitian 1300t (servo) used Injection Molding Machine – Toshiba Plastic Injection Molding Machine Detail:

Haitian 1300t (servo) used Injection Molding Machine for sale.

Model: MA13000/10500

Year: 2012.

Tie bar spacing: 1250mm.

Still running production in factory. Good working condition.

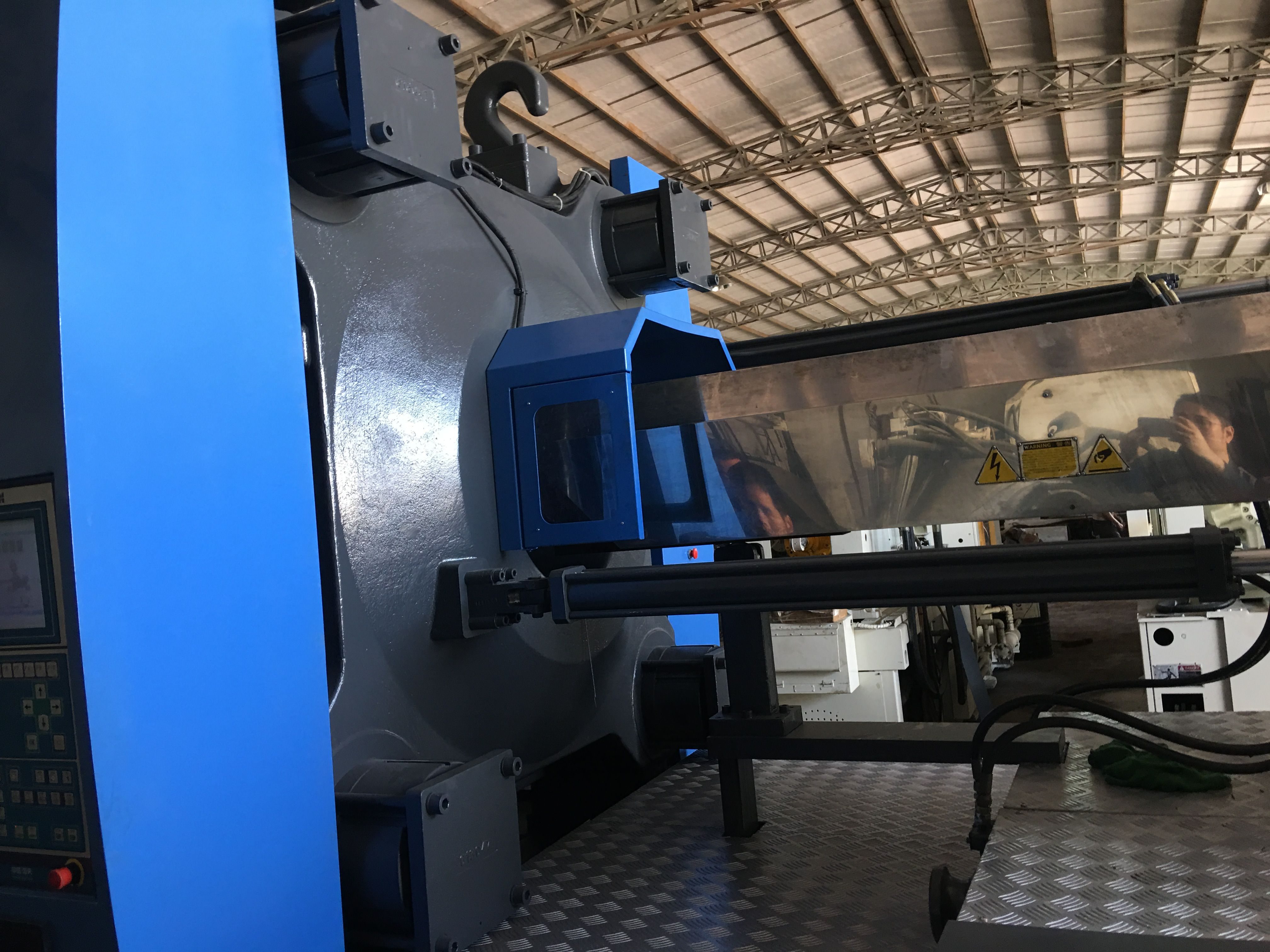

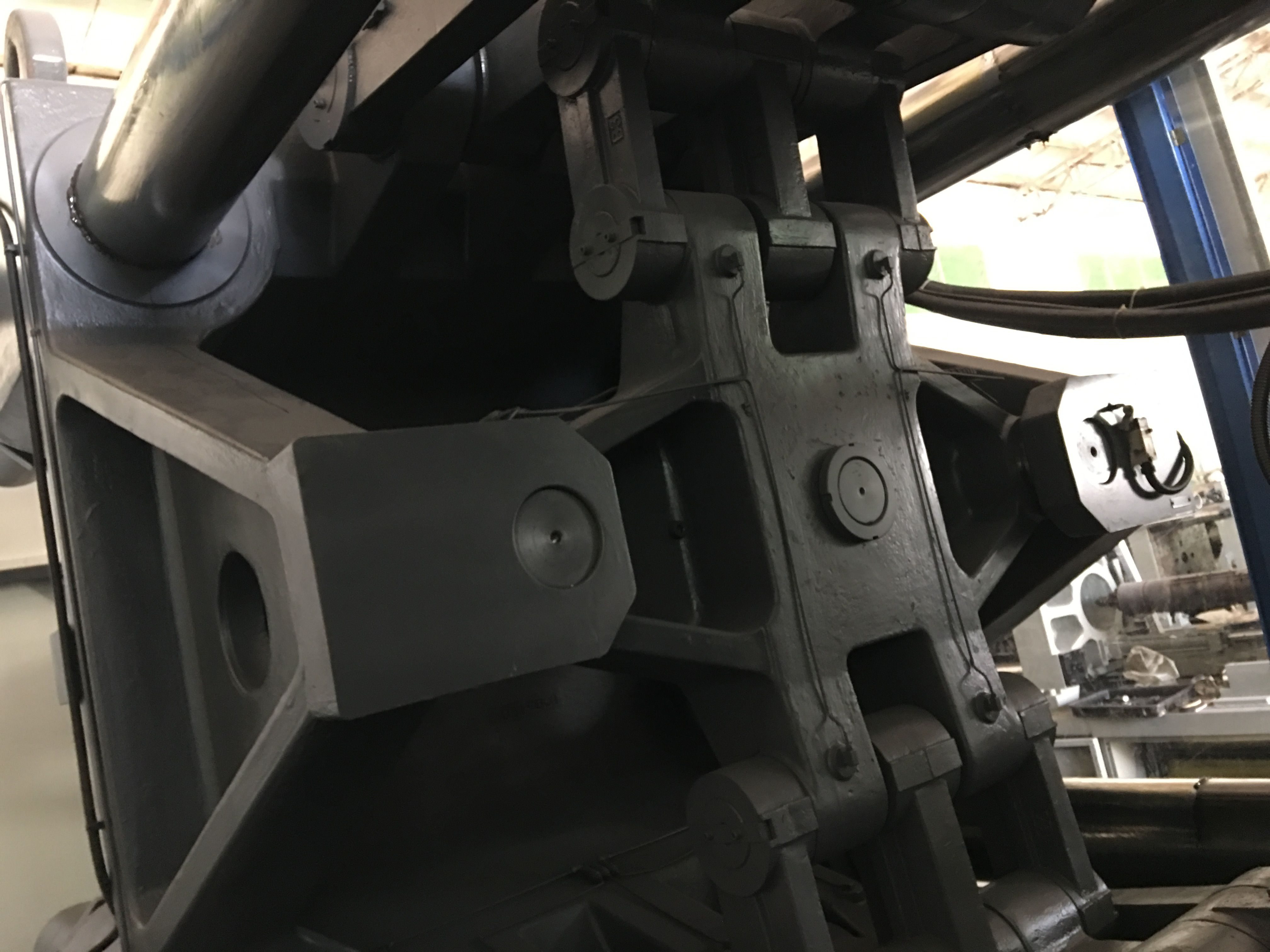

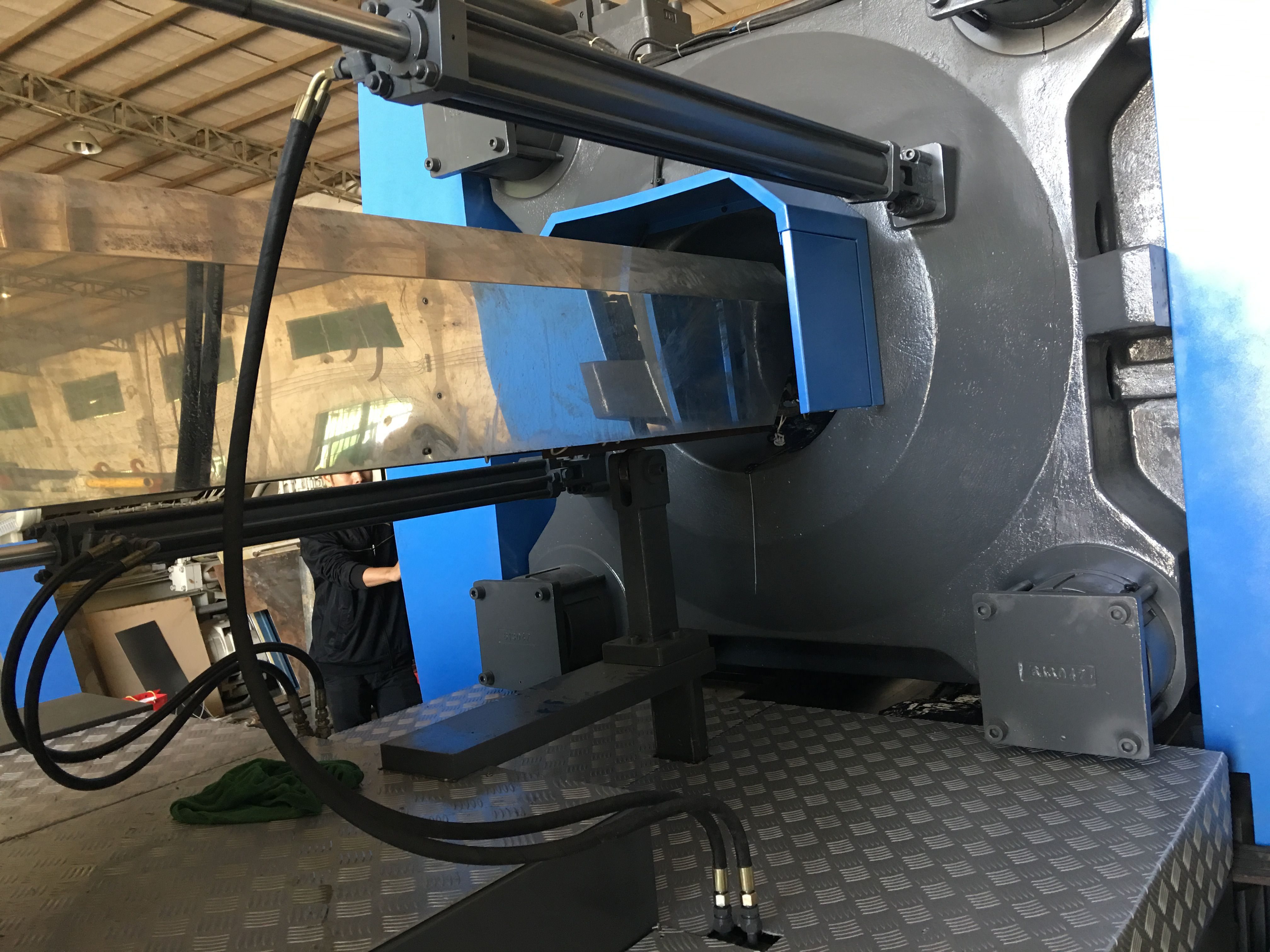

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Plastic Injection Molding: Past, Present and Future

We can always satisfy our respected customers with our good quality, good price and good service due to we are more professional and more hard-working and do it in cost-effective way for Factory made hot-sale Haitian 1300t (servo) used Injection Molding Machine – Toshiba Plastic Injection Molding Machine, The product will supply to all over the world, such as: Denver , Florida , Russia , Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to offer our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We are ready to face the worries and make the improve to understand all the possibilities in international trade.

more information available: www.uniplastico.com

Water Damage Restoration? Lindenhurst, NY Call (631) 888-6080 24/7, Call Now (613) 888-6080, or go to our website for more details. Open 24 Hours

https://westbabylonrestorationpros.com/

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.