Factory made hot-sale Niigata 450t All-electric used Injection Molding Machine for Rome Importers

Factory made hot-sale Niigata 450t All-electric used Injection Molding Machine for Rome Importers Detail:

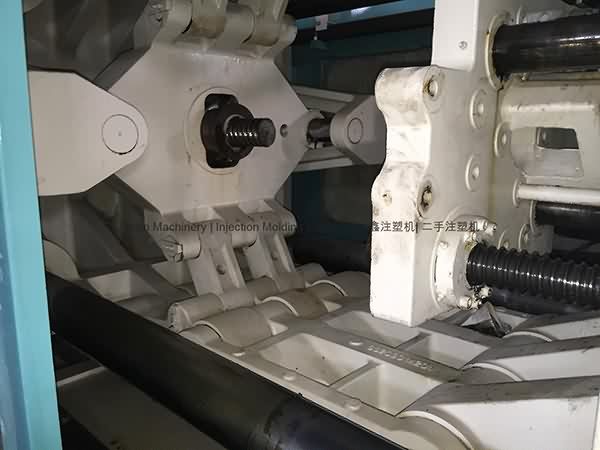

Niigata 450t All-Electric used Injection Molding Machine

Youtube Video: https://youtu.be/wHoMpY6lKng

Model: MD450S-IV.

Year: 2007.

Screw diameter: 82mm.

Tie bar spacing:820x820mm.

Injection Speed: 150mm/s.

Two units available. Interested customer is welcome to visit our warehouse to test machines running. Our warehouse is at Shenzhen, China (very near Hongkong and Guanzhou) .

Visit us after Chinaplas or Canton Fair!

Daxin Machinery

-Over 200 units of used injection molding machines in stock

-All can be inspected in the same warehouse under one roof

-All can be powered on for test-run in working condition

sales@daxin88.com / daxin88@hotmail.com

Skype: daxin-machinery / www.daxin88.com

Mobile: +8613509620296 (whatsapp) / +6596479097 (WeChat)

Follow Daxin Machinery: Facebook, Twitter, Google+, LinkedIn, Youtube.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Plastic Injection Molding: Past, Present and Future

Sticking to the principle of "Super Quality, Satisfactory service" ,We are striving to be a good business partner of you for Factory made hot-sale Niigata 450t All-electric used Injection Molding Machine for Rome Importers, The product will supply to all over the world, such as: Bangladesh , India , Naples , Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our items and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

Available for immediate sale and well maintained. Controls upgraded by Epco in 2003. Can be inspected in operation Contact IPC for more details ...

https://www.perfumeoils.com/index.php?p=product&id=1386.

High Quality, High Efficiency, Creative and Integrity, worth having long-term cooperation! Looking forward to the future cooperation!