Factory made hot-sale Sumitomo 130t All-Electric used Injection Modling Machine Supply to Denmark

Factory made hot-sale Sumitomo 130t All-Electric used Injection Modling Machine Supply to Denmark Detail:

Sumitomo 130t All-Electric Used Injection Molding Machine

Video: https://youtu.be/dh8sN_uCzjU

Model: SE130EV-C360HP.

Year: 2013.

Screw diameter: 25/28mm.

Injection Speed: 1000mm/s.

Tie bar spacing: 510x510mm.

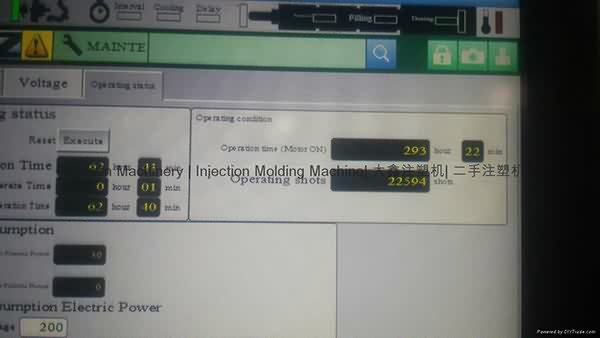

3 units. Machines are in very good and new running condition with less than 300 running hours. They are ultra high speed. Interested customers can visit our warehouse to inspect and test run machines.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

How Importers And Exporters Can Benefit From The Canton Fair

The organization upholds the philosophy of "Be No.1 in good quality, be rooted on credit history and trustworthiness for growth", will keep on to provide previous and new customers from home and overseas whole-heatedly for Factory made hot-sale Sumitomo 130t All-Electric used Injection Modling Machine Supply to Denmark, The product will supply to all over the world, such as: Ecuador , Latvia , Denver , Our company always concentrate on the development of the international market. We've got a lot of customers in Russia , European countries, the USA, the Middle East countries and Africa countries. We always follow that quality is foundation while service is guarantee to meet all customers.

Miles travels through Amish country while Bob tries to understand Miles weird neighbors. Come see Flat Manny, the amazing paper mail carrier! It's finally here ...

Staff is skilled, well-equipped, process is specification, products meet the requirements and delivery is guaranteed, a best partner!