Factory making Haitian 380t used Injection Molding Machine Export to Iraq

Factory making Haitian 380t used Injection Molding Machine Export to Iraq Detail:

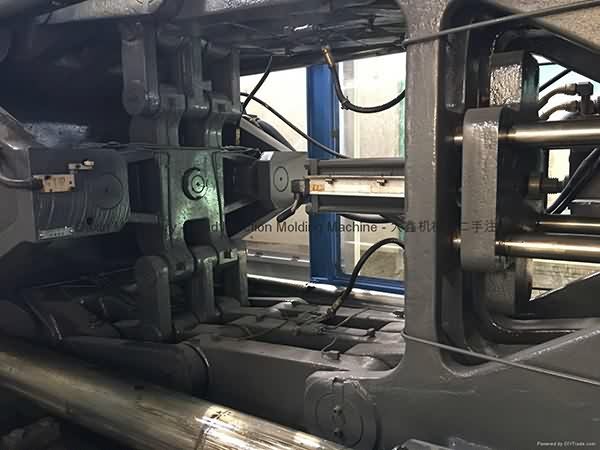

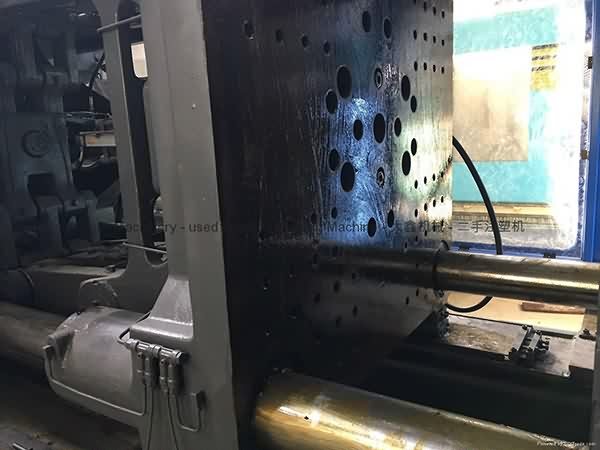

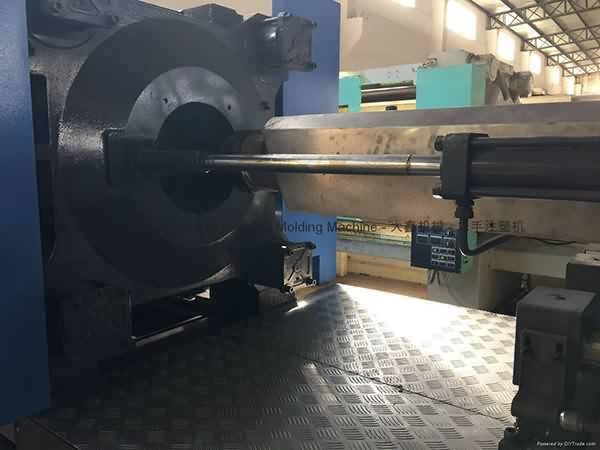

Haitian 380t used injection molding machine .

Model: SA3800/2250v.

Year : 2010.

Screw type: B-D70.

Tie bar spacing: 720x720mm

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

The Precision of Plastic Machining

"Quality to start with, Honesty as base, Sincere company and mutual profit" is our idea, as a way to build constantly and pursue the excellence for Factory making Haitian 380t used Injection Molding Machine Export to Iraq, The product will supply to all over the world, such as: Turkey , Pakistan , Moscow , We have won a good reputation among overseas and domestic clients. Adhering to the management tenet of "credit oriented, customer first, high efficiency and mature services", we warmly welcome friends from all walks of life to cooperate with us.

INJECTION MOULDING MACHINE FOR THERMOPLASTICS

PRESSE AD INIEZIONE PER TERMOPLASTICI

www.plasticmetal.it

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.