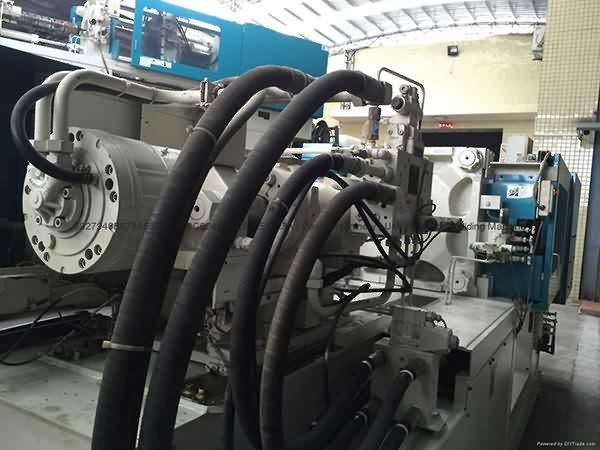

Factory making Mitsubishi 160t used Injection Molding Machine for Swiss Manufacturer

Factory making Mitsubishi 160t used Injection Molding Machine for Swiss Manufacturer Detail:

Mitsubishi 160t used Injection Molding Machines for sale.

Model: 160MSV.

Year: 2005.

Screw diameter: 45mm.

Tie bar spacing: 560m.

Very good running condition.

Interested customers can visit our warehouse to inspect the machine.

Product Image

Product detail pictures:

Related Product Guide:

Plastic Injection Molding: Past, Present and Future

Making Plastic – Plastic Injection Moulding

We're going to commit ourselves to giving our esteemed buyers using the most enthusiastically considerate solutions for Factory making Mitsubishi 160t used Injection Molding Machine for Swiss Manufacturer, The product will supply to all over the world, such as: Oman , Liverpool , Ethiopia , Customer satisfaction is our first goal. Our mission is to pursue the superlative quality, making continual progress. We sincerely welcome you to make progress hand in hand with us, and construct a prosperous future together.

Tutorial : Yushin RAII-a-150D-NC Full-Servo Traverse Robot Free online seo tools on bulkping for Website Seo Video Yushin, robotics, plastics, injection, ...

Double Shot injection or 2K moulding is referring to injection 2 material at the same time. This technique will help to save some assembly jobs.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.