Factory making Mitsubishi 160t used Injection Molding Machine – Servo Used Injection Molding Machine

Factory making Mitsubishi 160t used Injection Molding Machine – Servo Used Injection Molding Machine Detail:

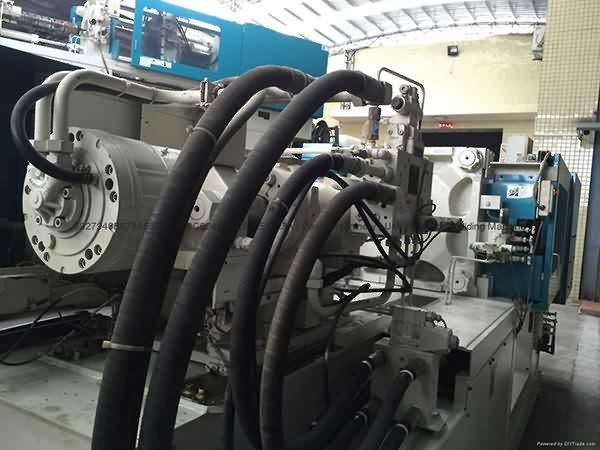

Mitsubishi 160t used Injection Molding Machines for sale.

Model: 160MSV.

Year: 2005.

Screw diameter: 45mm.

Tie bar spacing: 560m.

Very good running condition.

Interested customers can visit our warehouse to inspect the machine.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

Plastic Injection Molding: Past, Present and Future

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Factory making Mitsubishi 160t used Injection Molding Machine – Servo Used Injection Molding Machine, The product will supply to all over the world, such as: Ireland , Vietnam , Czech Republic , As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers, and establish a long term business relationship with buyers and users all over the world.

Chris Duke from Motorz TV https://www.motorz.tv shows you how to a nitrous oxide kit from Nitrous Express on a 2008 Ford Mustang GT (S197).

SUBSCRIBE FOR MORE: https://www.youtube.com/subscription_center?add_user=motorztv

Show notes: https://www.motorz.tv/nitrous-oxide/

Website: https://www.motorz.tv/

Facebook: https://www.facebook.com/motorztv

Twitter: https://twitter.com/motorz/

Bra sponge moulding machine, high efficiency

Please contact with Ms. Aileen for details:

Tel: +86 513 8762 8369

Fax: +86 513 8763 5890

Skype: honeyaileen1

Email: aileen@zhenhuan-machine.com

Web: www.zhenhuan-machine.com

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!