Factory Outlets CLF-1000T (servo) used Injection Molding Machine to Puerto Rico Factory

Factory Outlets CLF-1000T (servo) used Injection Molding Machine to Puerto Rico Factory Detail:

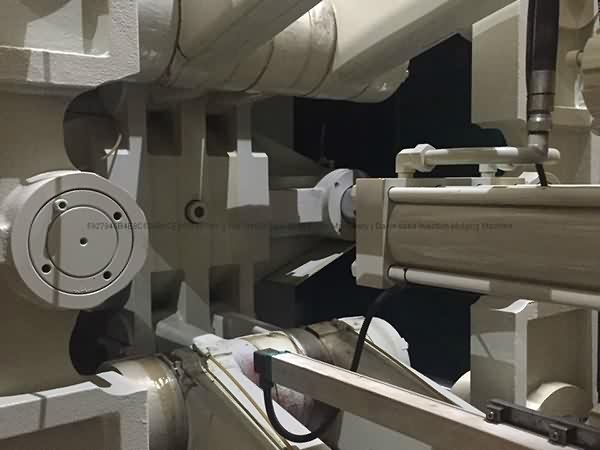

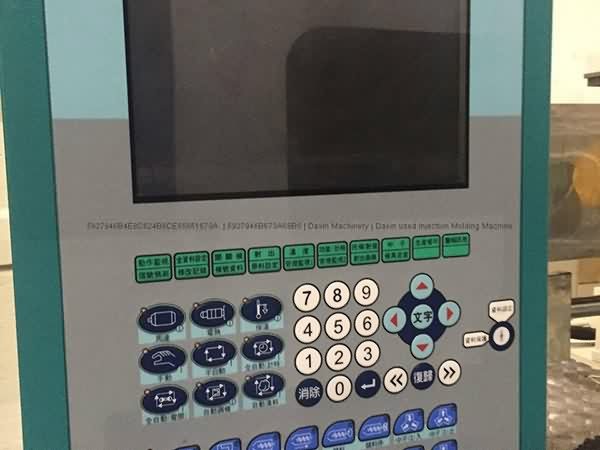

CLF-1000T (servo) used Injection Molding Machine.

Model: CLF-1000T.

Year: 2011.

Screw diameter: 105mm.

Tie bar spacing: 1060mm.

Very good working condition. Interested customer pls visit our warehouse to inspect the machine and test it running under power..

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

Making Plastic – Plastic Injection Moulding

Our concentrate on should be to consolidate and enhance the quality and service of present products, meanwhile consistently produce new products to meet unique customers' demands for Factory Outlets CLF-1000T (servo) used Injection Molding Machine to Puerto Rico Factory, The product will supply to all over the world, such as: USA , Barcelona , Ecuador , Over the years, with high-quality products, first- class service, ultra-low prices we win thee trust and favor of customers. Nowadays our products sell all over the domestic and abroad. Thanks for the regular and new customers support. We provide high quality product and competitive price, welcome the regular and new customers cooperate with us!

CCM continuous compression moulding hydraulic press for plastic cap manufacturing via the extrusion of dry-blend granulated compounds (i.e. HDPE, PP). The new CCM 48 SC has a cycle time of just 1.8 seconds. https://goo.gl/pnAxO9

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!