Factory Outlets Donghua 320t (variable pump) used Injection Molding Machine for Italy Factory

Factory Outlets Donghua 320t (variable pump) used Injection Molding Machine for Italy Factory Detail:

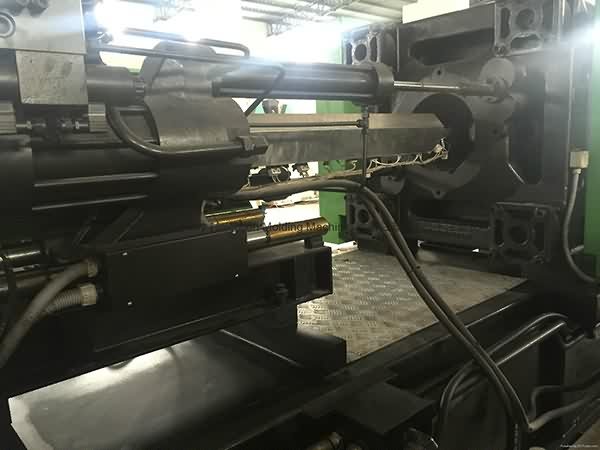

Taiwan Donghua 320t injection molding machine (Variable pump).

YoutubeVideo: https://youtu.be/6LtP9BF6UnA

Model: TTI-320F2V.

Year: 2012.

Screw diameter: 55mm.

Tie bar spacing: 660x660mm.

Machine is in good running condition with variabl pump. Interested customer can inspect machine.

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Making Plastic – Plastic Injection Moulding

Dedicated to strict high-quality management and considerate shopper company, our experienced team associates are normally available to discuss your requirements and ensure full shopper gratification for Factory Outlets Donghua 320t (variable pump) used Injection Molding Machine for Italy Factory, The product will supply to all over the world, such as: Istanbul , Anguilla , Philippines , With the aim of "compete with good quality and develop with creativity" and the service principle of "take customers' demand as orientation", we will earnestly provide qualified products and solutions and good service for domestic and international customers.

Company website: www.cnmolder.com For any suggestion please contact focaremould@yahoo.com Thank you. Lucia.

Exclusive Repairs @ Advanced Micro Services Pvt,Ltd,www.amsindia.net,

Contact Person:MalateshPatil,+919900565861,patil@amsindia.net

Address: Advanced Micro Services Pvt. Ltd

# 305,3rd Floor,Annexe-E Block,Brigade MM,Jayanagar,7th Block K R Road, Bangalore-560082, India

Website:www.amsindia.net

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!