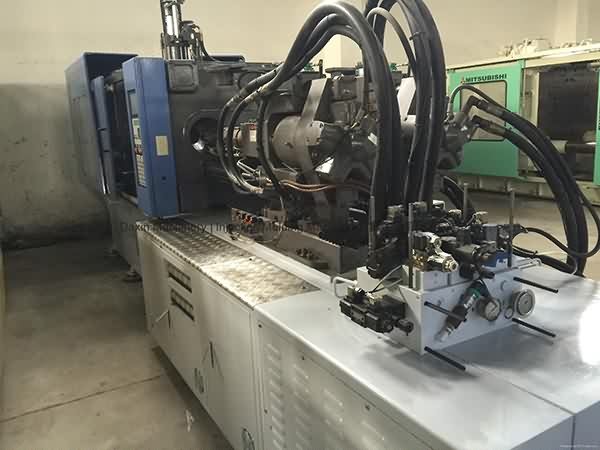

Factory Outlets Hwa Chin 350t double-color used Injection Molding Machine to Manila Importers

Factory Outlets Hwa Chin 350t double-color used Injection Molding Machine to Manila Importers Detail:

Taiwa Hwa Chin 350t Double Color used Injection Molding Machine.

Model: DC-350.

Year: 2010.

Screw diameters: 32/32mm.

Tie bar spacing: 650x650mm.

Diameter of rotary table: 950mm.

Very good running condition. Interested customer can visit our warehouse after Chinaplas to inspect and test machine running.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Making Plastic – Plastic Injection Moulding

Our rewards are reduce selling prices,dynamic revenue team,specialized QC,sturdy factories,superior quality services for Factory Outlets Hwa Chin 350t double-color used Injection Molding Machine to Manila Importers, The product will supply to all over the world, such as: Thailand , Mozambique , Jordan , Our products are exported worldwide. Our customers are always satisfied with our reliable quality, customer-oriented services and competitive prices. Our mission is "to continue to earn your loyalty by dedicating our efforts to the constant improvement of our products and services in order to ensure the satisfaction of our end-users, customers, employees, suppliers and the worldwide communities in which we cooperate".

Exclusive Repairs @ Advanced Micro Services Pvt,Ltd,www.amsindia.net,

Contact Person:MalateshPatil,+919900565861,patil@amsindia.net

Address: Advanced Micro Services Pvt. Ltd

# 305,3rd Floor,Annexe-E Block,Brigade MM,Jayanagar,7th Block K R Road, Bangalore-560082, India

Website:www.amsindia.net

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.