Factory Price For Chen Hsong Super Master SM450TS used Injection Molding Machine to Angola Importers

Factory Price For Chen Hsong Super Master SM450TS used Injection Molding Machine to Angola Importers Detail:

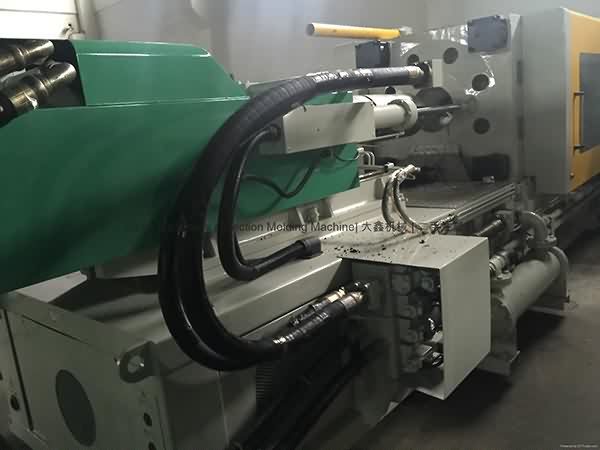

Taiwan Chen Hsong Super Master 450t used Injection Molding Machine

Video: https://youtu.be/lo5SPPvPMCo

Model: SM450TS.

Year 2009.

Screw diameter: 60mm.

Tie bar spacing: 820x820mm.

High precision. Very good running condition. Interested customer is welcome to visit our warehouse to inspect the machine and power it on to test run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

We insist on offering premium quality manufacturing with superior business concept, honest product sales as well as finest and fast assistance. it will bring you not only the good quality product or service and huge profit, but the most significant is to occupy the endless market for Factory Price For Chen Hsong Super Master SM450TS used Injection Molding Machine to Angola Importers, The product will supply to all over the world, such as: Macedonia , Chicago , Switzerland , Our products have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll provide the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

MICROTEC ENGINEERING GROUP is engineering company in Australia . It explains corn starch production process . It has many photos showing machinery and equipment for corn starch production. By watching this presentation you would get a general idea of corn starch production process .

For more information you can visit www.microtecco.com

Electric motor Armature repair, NEVER TRY THIS EVER! Electricity can and will kill you if your are not careful, if you have a bad armature, replace it, do not try to repair it, this only shows you the mechanics of an armature and this probably won't last long. I ended up using a brass brush instead, the copper did not last long, and don't forget to clean your graphite brushes with light sanding. I also put a heat resistant ring around both ends of the armature brushes cut out of tubing and glued them in, this worked good at holding the brush in place. Any time you experiment with motors they can hold a spark for a long time after you are done so make sure you watch your project for a while after to prevent any fire hazard. Again don't ever do this just replace the armature with a brand new one, or better yet get a new tool. The cost for a new tool is similar to an armature cost, this is desert island science, for those people stranded on an island with nothing but spare parts. keep inventing'

Problems can be quickly and effectively resolved, it is worth to be trust and working together.