Factory Price Mitsubishi 1300t Used Injection Molding Machine for Mexico Manufacturers

Factory Price Mitsubishi 1300t Used Injection Molding Machine for Mexico Manufacturers Detail:

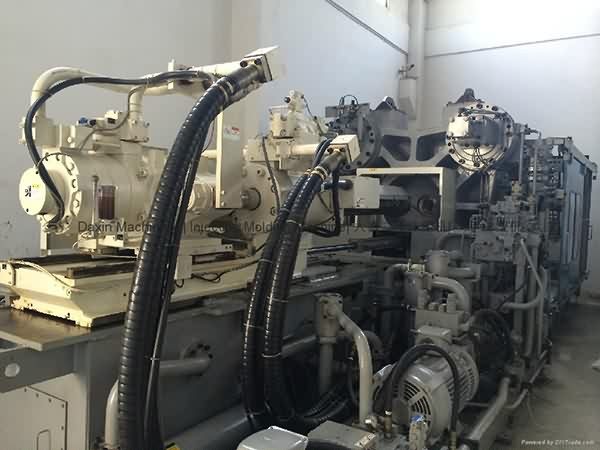

Mitsubishi 1300t used Injection Molding Machine.

Model: 1300MMV-160.

Year of manufactue: 2011.

Tie bar spacing: 1320x1280mm.

Screw diameter: 100mm.

Injection volume: 4540cm^3.

Mould thickness: 700~1200mm.

Clamp stroke: 1800mm.

Machine is in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou. Interested customers can visit us to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

The Precision of Plastic Machining

We have a professional, efficiency team to provide quality service for our customer. We always follow the tenet of customer-oriented, details-focused for Factory Price Mitsubishi 1300t Used Injection Molding Machine for Mexico Manufacturers, The product will supply to all over the world, such as: Jeddah , Rio de Janeiro , Mexico , We now have established long-term, stable and good business relationships with many manufacturers and wholesalers around the world. Currently, we've been looking forward to even greater cooperation with overseas customers based on mutual benefits. You should feel free to contact us for more details.

Automatic blow molding machine for making plastic balls!

Full auto deflashing with conveyor

ball Production per hour 3000 pcs

Screw 75mm, parison controller available

Know more details, please contact:

Mr Ken (Export Manager)

Co: Dawson Machinery & Mould Group Co.,Ltd

Zhangjiagang Apollo Machinery Co.Ltd

Add: TianZhuang Of FengHuang Town,Zhangjiagang

City,JiangSu Province,China

Tel: 0086-512-58990369 Mob: 0086-13913143237

Skype: t542892865

MSN: kenmartin2009@hotmail.com

E-mail: kenmartin520@gmail.com

Yahoo: kenmartin2003@yahoo.com

Website: www.dawson-plastic.com

Simufact, sayısal simülasyon yazılımı geliştirme konusunda sektörün en büyük firması olan MSC Software grubu içerisinde yer almaktadır ve geliştirdiği Simufact Forming, Simufact Welding ve Simufact Additive programları ile soğuk, ılık ve sıcak dövme, kütlesel ve sac metal şekillendirme, profil ve yüzük haddeleme, mekanik birleştirme, ısıl işlem; ark, lazer ve punta kaynağı ile eklemeli üretim prosesleri hızlı ve doğru şekilde bilgisayar ortamında analiz edilebilmektedir.

Ayrıltılı bilgi için internet sayfamızı ziyaret edebilirsiniz.

https://www.netformmetal.com

NETFORM Mühendislik Makina Metal

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.