Factory Price Nanrong 120t used Injection Molding Machine for Montreal Factory

Factory Price Nanrong 120t used Injection Molding Machine for Montreal Factory Detail:

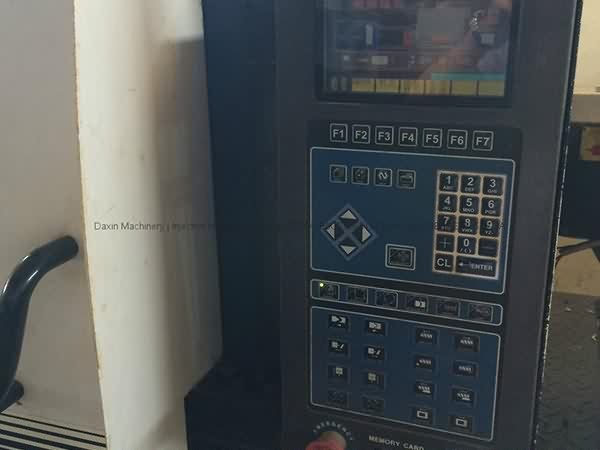

Taiwan Nanrong 120t Used Plastic Injection Molding Machine

Youtube Video: https://youtu.be/Dpld0N3LLpk

Model: 120SA

Tonnage: 120t

Screw diameter: 22mm

Tie bar spacing: 360x360mm

Year: 2006

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou.Interested customers can visit us after Chinaplas to power on machines for test-run.

Product Image

Product detail pictures:

Related Product Guide:

How Importers And Exporters Can Benefit From The Canton Fair

Plastic Injection Molding: Past, Present and Future

With our leading technology also as our spirit of innovation,mutual cooperation, benefits and development, we are going to build a prosperous future jointly with your esteemed company for Factory Price Nanrong 120t used Injection Molding Machine for Montreal Factory, The product will supply to all over the world, such as: Greenland , Denver , Guatemala , To let customers be more confident in us and get the most comfortable service, we run our company with honesty, sincerity and best quality . We firmly believe that it is our pleasure to help customers to run their business more successfully, and that our professional advice and service can lead to more suitable choice for the customers.

A small current controlled by an Arduino is being used to close the primary circuit of a relay. The relay, in turn, is using a nine volt battery on the secondary circuit ...

Superb technology, perfect after-sales service and efficient work efficiency, we think this is our best choice.