Factory Promotional Haitian 250t (servo) used Injection Molding Machine Export to Cambodia

Factory Promotional Haitian 250t (servo) used Injection Molding Machine Export to Cambodia Detail:

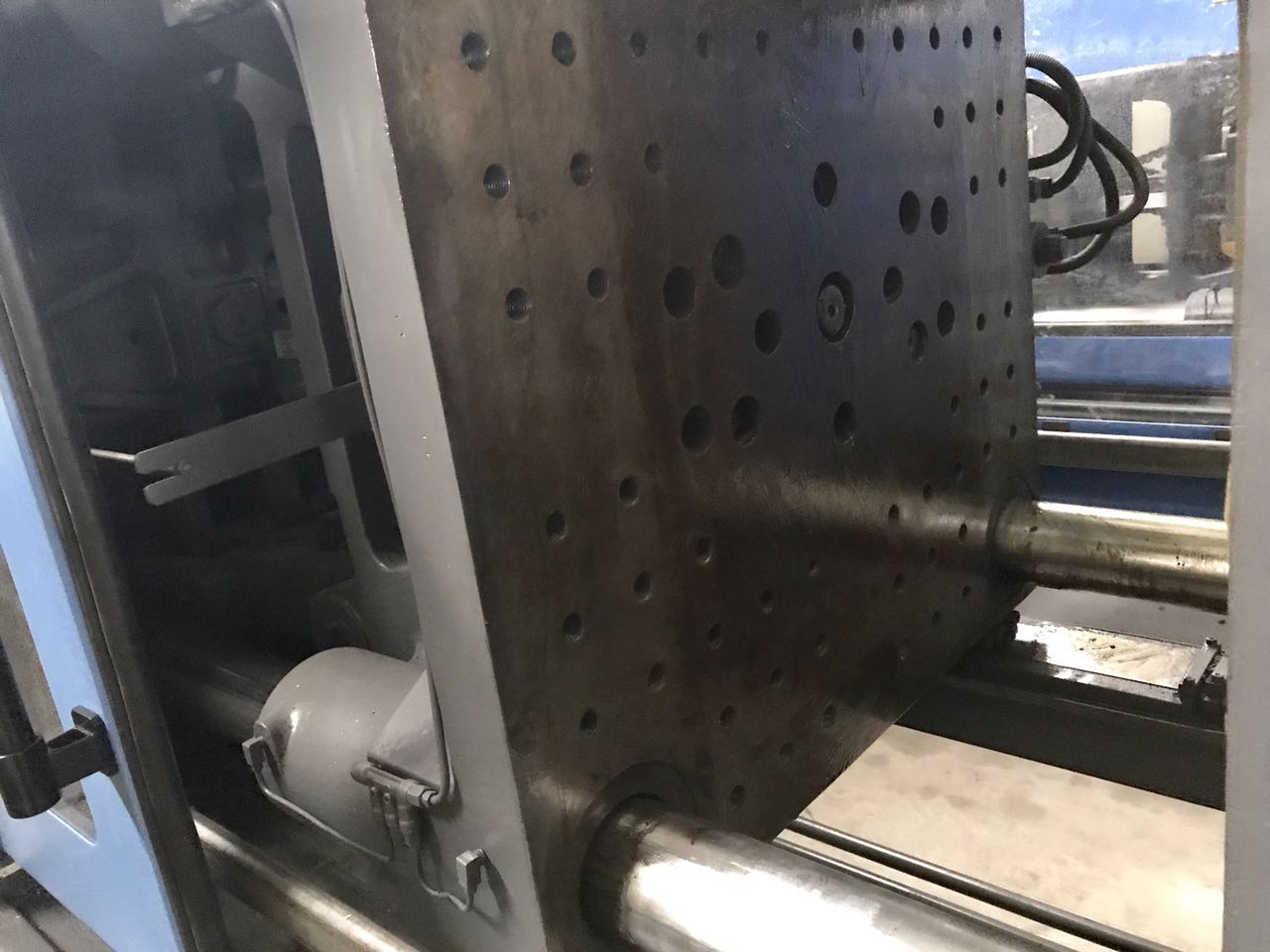

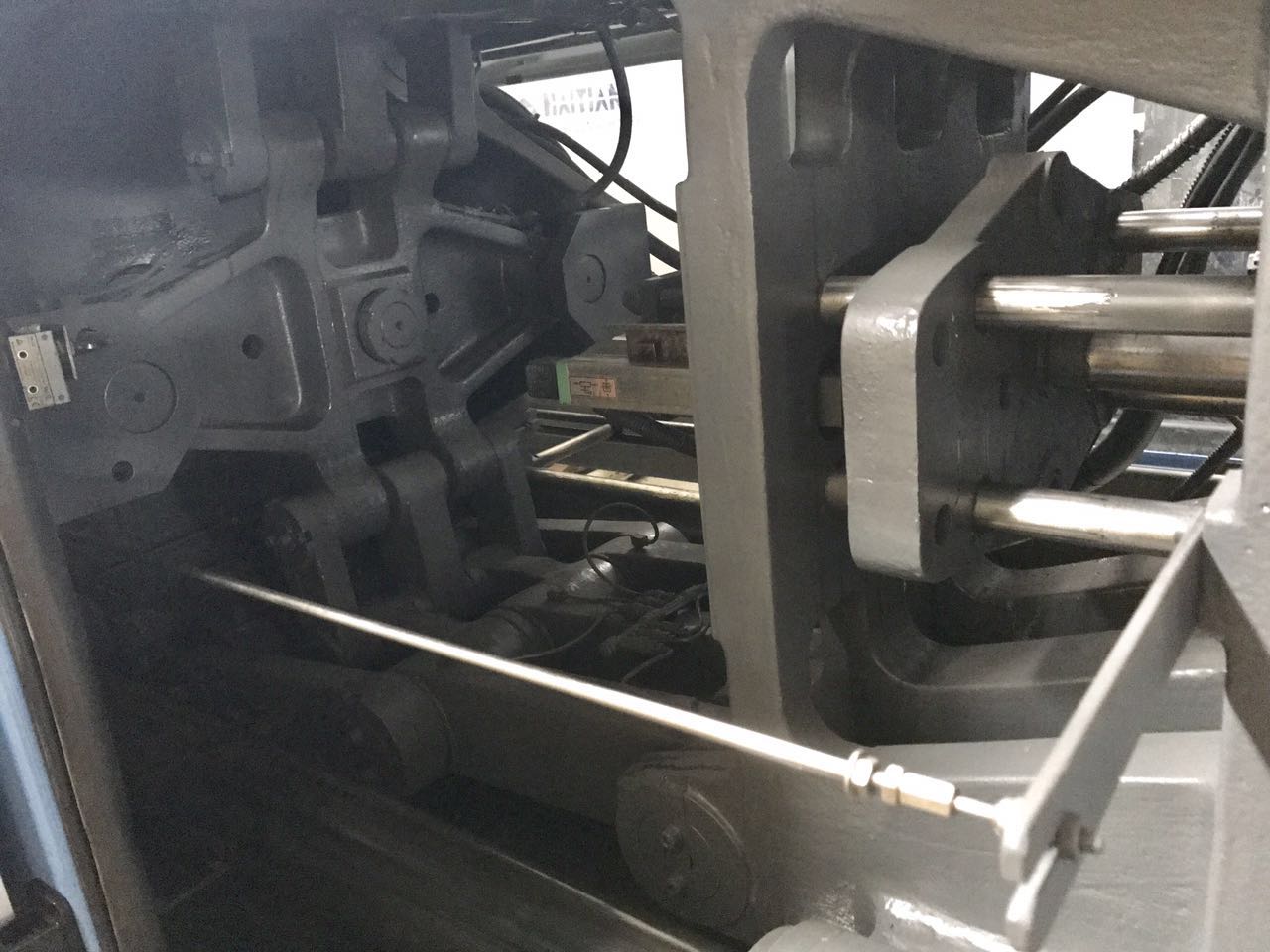

Haitian 250t (servo) used Injection Molding Machine.

Model: MA250.

Year: 2012.

Tie bar spacing: 580x580mm.

Good working condition.

Product detail pictures:

Related Product Guide:

Making Plastic – Plastic Injection Moulding

Plastic Injection Molding: Past, Present and Future

We follow our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create much more worth for our buyers with our abundant resources, highly developed machinery, experienced workers and great providers for Factory Promotional Haitian 250t (servo) used Injection Molding Machine Export to Cambodia, The product will supply to all over the world, such as: Myanmar , Houston , Saudi Arabia , Certainly, competitive price, suitable package and timely delivery will be assured as per customers' demands. We sincerely hope to build business relationship with you on the basis of mutual benefit and profit in the very near future. Warmly welcome to contact us and become our direct cooperators.

More info: https://www.machinepoint.com/machinepoint/inventory.nsf/idmaquina/300033449?OpenDocument&ln=en&origin=YouTube Email: ...

WE ARE THE BEST PLASTIC MACHINE SUPPLIER: PET semi-automatic stretch blow molding machine Automatic stretch blow moulding machine ...

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.