Factory Promotional Nanrong 120t used Injection Molding Machine to Oman Manufacturers

Factory Promotional Nanrong 120t used Injection Molding Machine to Oman Manufacturers Detail:

Taiwan Nanrong 120t Used Plastic Injection Molding Machine

Youtube Video: https://youtu.be/Dpld0N3LLpk

Model: 120SA

Tonnage: 120t

Screw diameter: 22mm

Tie bar spacing: 360x360mm

Year: 2006

Machines are in good working condition,kept in our warehouse at ShenZhen of China, very near HongKong and GuangZhou.Interested customers can visit us after Chinaplas to power on machines for test-run.

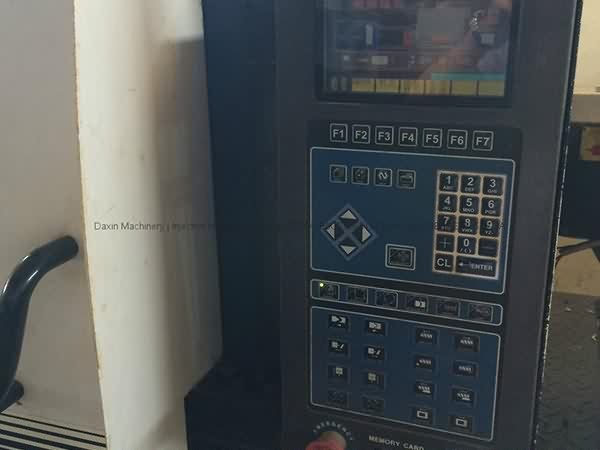

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

The Emergence of Injection Molding in Plastic Industry

To create much more benefit for consumers is our company philosophy; customer growing is our working chase for Factory Promotional Nanrong 120t used Injection Molding Machine to Oman Manufacturers, The product will supply to all over the world, such as: Belgium , Morocco , Switzerland , We integrate all our advantages to continuously innovate, improve and optimize our industrial structure and product performance. We will always believe in and work on it. Welcome to join us to promote green light, together we will make a better Future!

20,000Lb Used CAT Forklifts For Sale 616-200-4308 for more details go to https://d1a6prx2duc1gy.cloudfront.net/ or contact us at 616-200-4308. Inventory changes often, contact us for current inventory. Go here: https://d26fito5xtoopf.cloudfront.net We also buy and sell forklifts. Capacities from 15,000lb, 20,000lb, 30,000lb, 40,000lb, 60,000lb and 80,000lb for sale.

Used CAT, 20,000lb, Forklifts For Sale 616-200-4308

https://commondatastorage.googleapis.com/usedmachinery/used-large-capacity-forklifts-sale-fork-trucks/index.html

https://youtube.com/watch?v=XpUNcq2iMyI

More product details are at https://www.apsx.com/product-p/apsx_pim.htm MADE in CINCINNATI, OH USA. If you like to watch YouTube videos for basic practical ...

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.