Factory Promotional Toshiba 1300t (wide platen) used Injection Molding Machine to Ethiopia Factory

Factory Promotional Toshiba 1300t (wide platen) used Injection Molding Machine to Ethiopia Factory Detail:

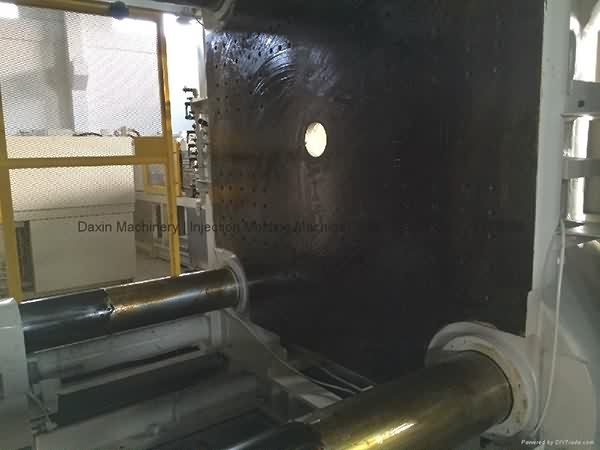

A Toshiba 1300t (wide platen) used injection molding machine for sale.

Model: IS1300DFW-200A.

Year of manufacture: 2004.

Screw diameter: 140mm.

Shot weight:9150g.

Tie bar spacing: 1430x1430mm.

Youtube video: https://youtu.be/hRc5cZvXlFs

Machine has wide platen, it is in good running condition. Interested customer is welcome to visit our warehouse to inspect and test run the machine.

Product Image

Product detail pictures:

Related Product Guide:

The Emergence of Injection Molding in Plastic Industry

How Importers And Exporters Can Benefit From The Canton Fair

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for Factory Promotional Toshiba 1300t (wide platen) used Injection Molding Machine to Ethiopia Factory, The product will supply to all over the world, such as: Armenia , Uruguay , Denver , we are fully determined to control the whole supply chain so as to provide quality products at competitive price in a timely manner. We are keeping up with the advanced techniques, growing through creating more values for our clients and society.

Dubai Plastic Industry.We are making different plastic items such as Lota,Jaar Watar Coolar etc on oder.cell No 00923459009609,and 00923008588785 and00923219009609.www.dubaiplastic.com.pk

www.enjeksiyondaikinciel.com Gsm: 0532 251 02 98.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!