Factory selling CLF-200TY used Injection Molding Machines for Berlin Factory

Factory selling CLF-200TY used Injection Molding Machines for Berlin Factory Detail:

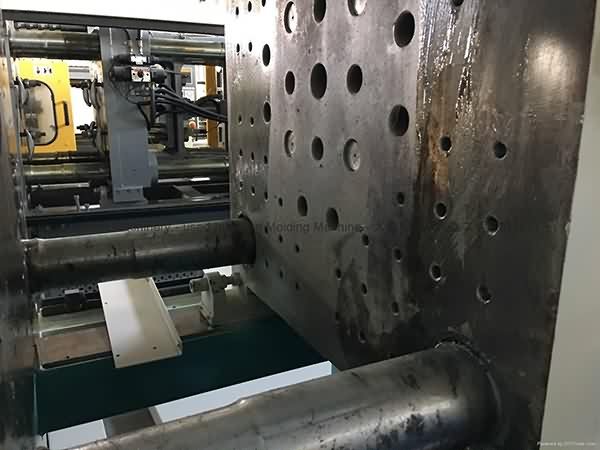

CLF-200TY used Injection Molding Machine.

Model; CLF-200TY.

Year: 2012.

Tie bar spacing: 560x560mm.

Two units available. Very good working condition. Interested customer can visit our warehouse to inspect the machines and test them running under power..

Product Image

Product detail pictures:

Related Product Guide:

The Precision of Plastic Machining

Plastic Injection Molding: Past, Present and Future

We pursue the administration tenet of "Quality is exceptional, Assistance is supreme, Reputation is first", and will sincerely create and share success with all clients for Factory selling CLF-200TY used Injection Molding Machines for Berlin Factory, The product will supply to all over the world, such as: Provence , Turkmenistan , Poland , If you give us a list of merchandise you are interested in, along with makes and models, we can send you quotations. Remember to email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

Hard plastic regrind recycling machine - Model TR-100V Polystar(Taiwan) - Original manufacturer of Hard plastic regrind recycling machine Send your inquiry ...

Manufacturer: Toshiba Model No.: 840M71/ISF90PVL Inventory No.: 0616-226-0107 Aisle: 12A Weight (lbs.): 8215 Price (current as of 7/12/16): $4999 15'' x 23'' ...

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!